Ultra-High Vacuum Feedthroughs

Our modular feedthroughs use unique joining technology that offers electrical and optical connectivity in ultra-high vacuum applications.

Feedthroughs for the most extreme environmental conditions

One of the most critical yet often overlooked components in any system where probes, sensors, electrodes, wires and other types of static elements need to pass through a pressure or environmental boundary, are feedthroughs. These need to provide a seal often under the most extreme environmental conditions. LouwersHanique’s unique joining technology and the application of preferred materials and material combinations ensure that functionality is guaranteed across a wide range of temperatures, from cryogenic to high temperatures. Contact our engineering team for further specifications.

Download our brochure

Why use glass and ceramics in feedthroughs

Metals are often the first-choice materials when it comes to ultra-high vacuum applications, especially feedthroughs. However, when dealing with cryogenic or high temperatures, high vacuums, and aggressive chemicals, only metal is often not enough. As the technology progresses so do the demands and needs for more advanced solutions. As a result, joining, and bonding technologies become increasingly more important. Glass-to-metal and ceramics-to-metal bonds can be used to achieve deeper vacuum and cope with a wider range of expansion coefficients than metals alone.

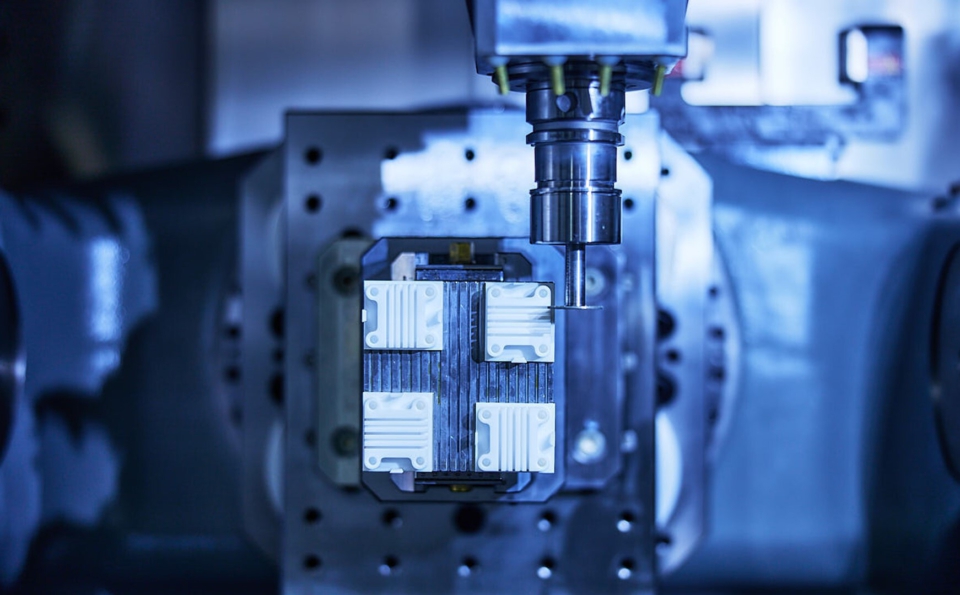

Joining technologies for high-performance components

Thanks to years of experience, our engineers have accrued boundless know-how regarding the optimization of matching materials. Direct bonding of glass with various types of metal delivers unprecedented integration and unique high-performance functionality. Ensuring a perfect join that meets the highest demands for Ultra-High Vacuum (UHV) and Ultra Clean Vacuum (UCV) systems. This enables us to manufacture custom-made feedthroughs for almost any application, including electrical feedthroughs, optical and high voltage feedthroughs.

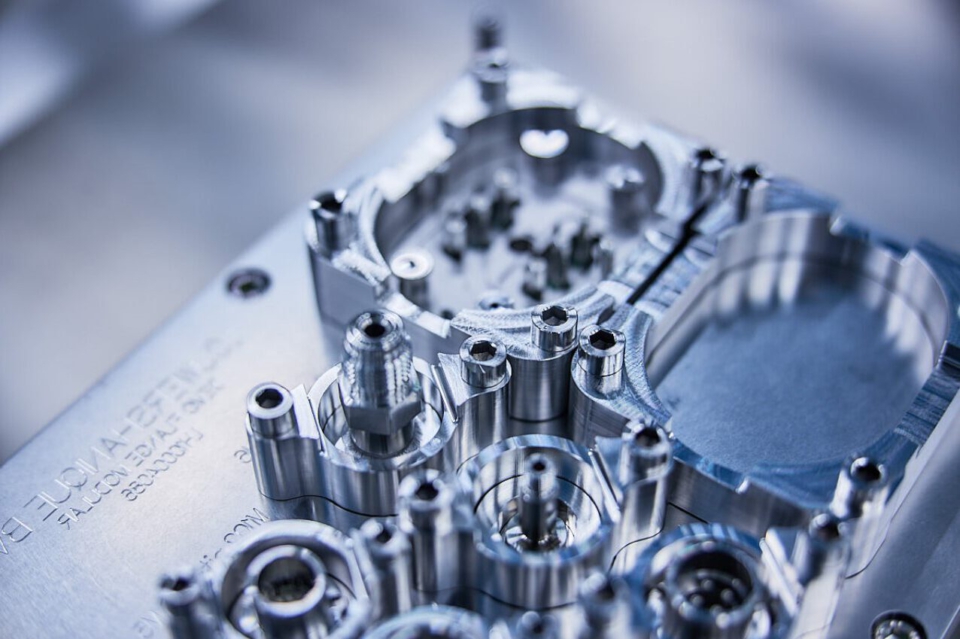

The ultimate feedthrough

Our high-quality and customer-specific electrical and optical modular feedthrough products provide customers with the ultimate feedthrough in terms of outgassing and purity, as well as functionality and reliability.

The modular feedthrough offered by LouwersHanique allows you to choose and implement the optimal combination of signals yourself.

Our feedthroughs are used in the most demanding applications, including lithography, electron microscopy, and challenging offshore solutions where temperature and/or magnetism are key

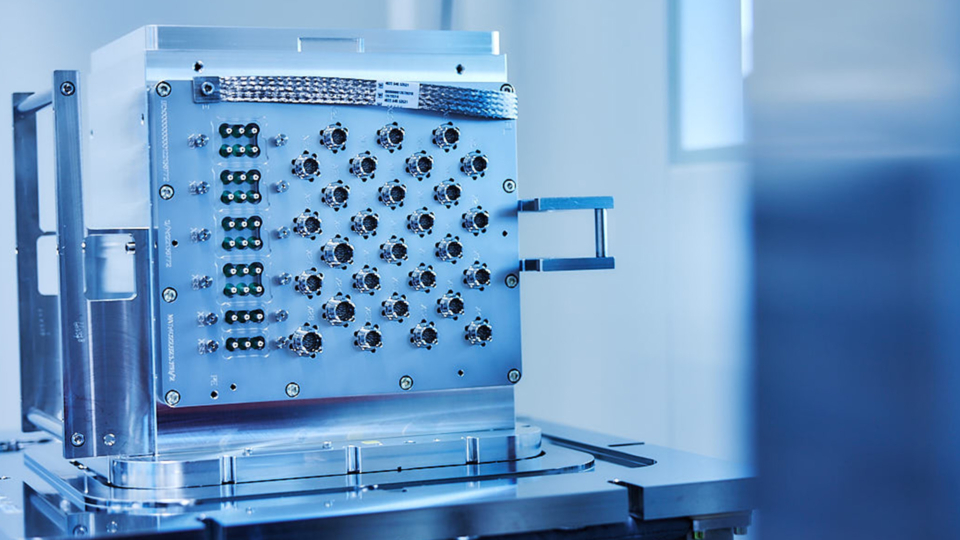

Typical solutions

- Many connector types are available - sub-D, Harting, LEMO and optical fiber

- Almost any combination is possible on a custom basis – from low-noise coaxial to high power, high voltage, optical, CAT6, multiple fiber feedthrough, etc.

Typical applications

- Ultra-High Vacuum systems (UHV).

- Micro-lithography.

- Scanning Electron Microscopes (SEMs).

- Mass spectroscopy systems.

- Cryogenic systems.

- Vacuum chamber systems.

- E-beam columns for metrology applications.

- Highly demanding offshore solutions.

- Non-magnetic products.

- Semicon wafer and reticle inspection systems.

Typical material combination

Our ceramic and metal material combinations are directly bonded using technical glass seals.

Metals

- SST 316L, 304L

- Alloy C22

- Tungsten

- Titanium

- Molybdenum

- Nickel alloys

Ceramics

- 97,6% Al2O3

- 99,5% Al2O3

- 99,7% Al2O3

- 99,8% Al2O3

- Zirconia

- Macor

- Zerodur

For alternative material combinations and custom-made solutions, please contact us.