UHV and Pressure Components

High-pressure & vacuum components, for the most demanding industries. Our automated production processes ensure stringent quality and performance criteria.

Understanding market requirements

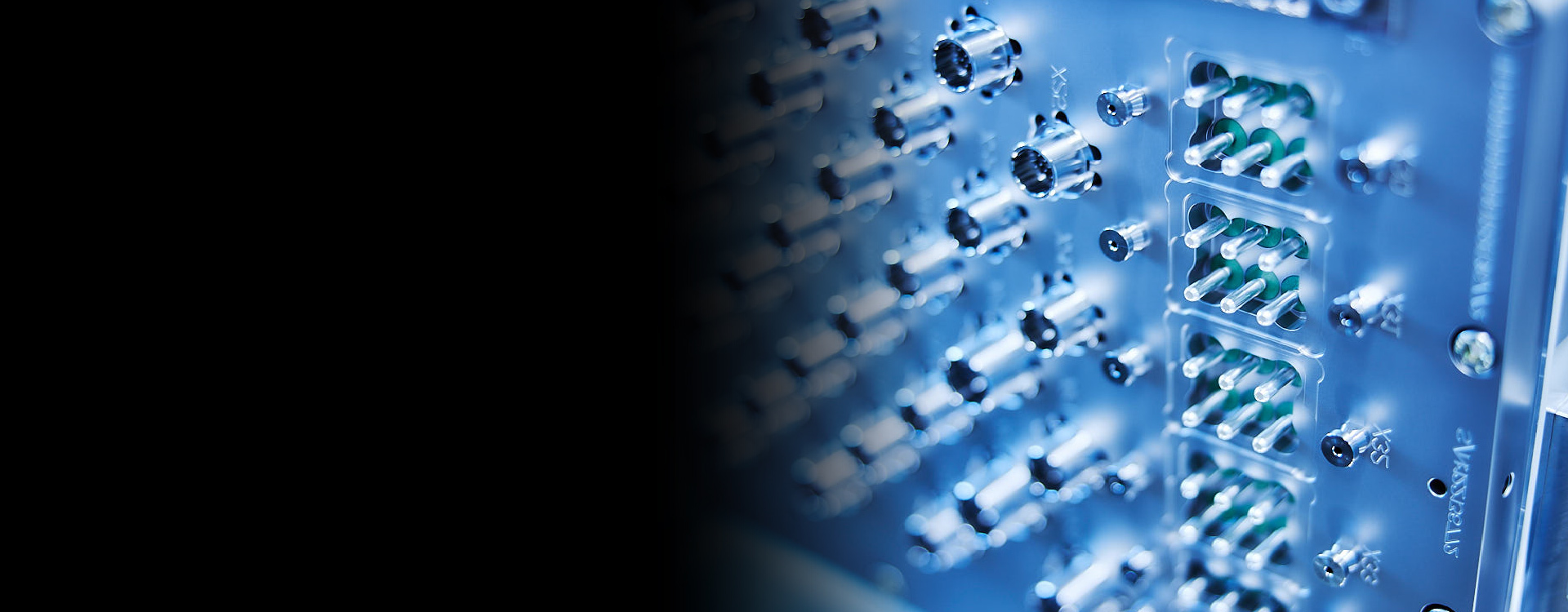

Today’s use of high-pressure and vacuum components and feedthroughs has grown substantially. Fuelled by applications with requirements for higher temperatures, pressure ranges, and harsh environments. Nevertheless, various industries are challenged with higher leak tightness specifications combined with technical strength and insulation properties. Having produced glass and ceramic components for customers primarily within Industrial & Energy and Semiconductors markets, we understand the nuances of these functional properties and criteria.

Stringent quality and performance criteria

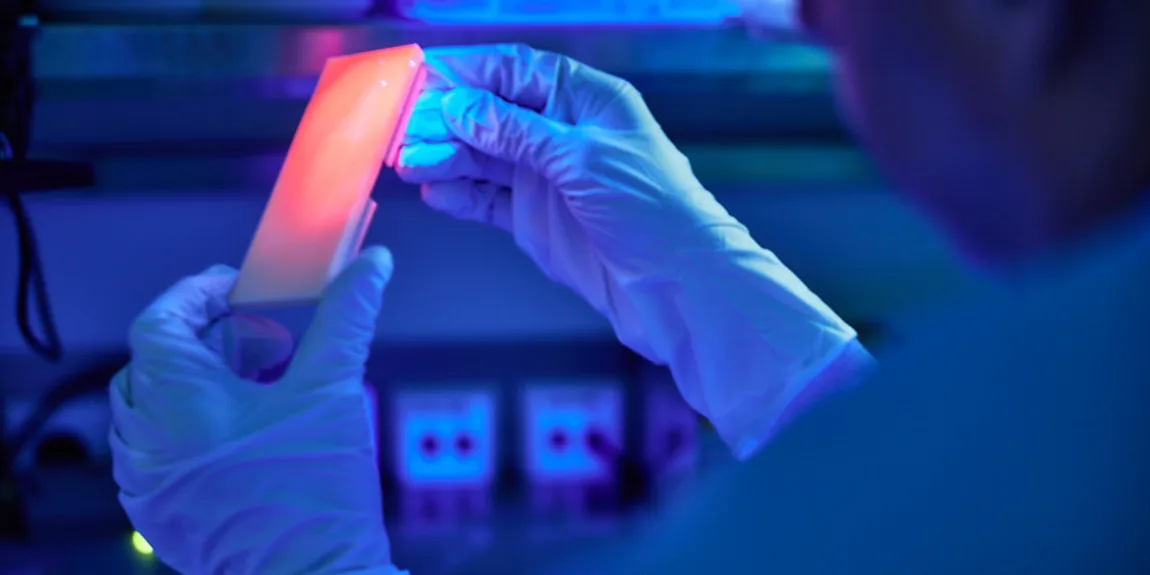

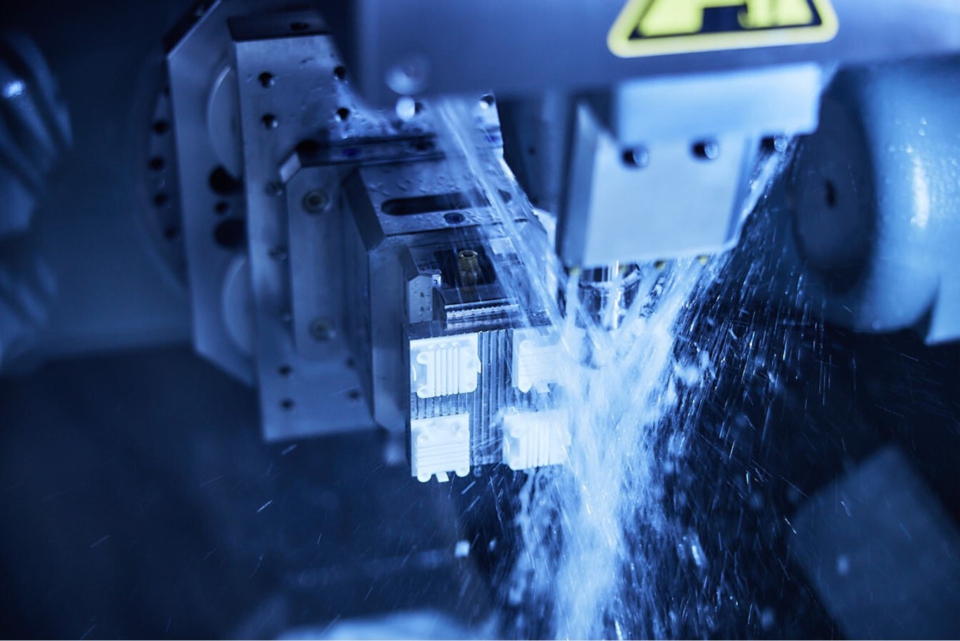

High-vacuum components are found in a range of applications where organic contaminants and particles need to be carefully managed or eliminated. We serve clients in the most demanding industries, where our products meet the lowest possible outgassing specifications in extreme conditions and environments. Our World Class Manufacturing processes ensure consistency and lifetime performance. Automation minimizes manual handling, which is one of the main root causes for the contamination of parts. This makes it possible to reach higher cleanliness levels, which is essential for UHV and UCV requirements. Today, we use automated machines to manufacture high-tech glass and ceramics components. This allows us to make large-, small-scale, and miniature components using technologies like automated lathe grinding, filament cutting, SLE and other laser and thermal processing, shaping, etching, and bonding methods. As a result, we deliver consistent quality, unlike any other glass and ceramics component manufacturer.

Precisely machined and bonded to be leak-tight

More than 70 years of experience in manufacturing has allowed us to master the knowledge and skills necessary for high and ultra-high vacuum component manufacturing. The most critical specification is hermeticity when it comes to meeting the requirements for vacuum and high-pressure applications. Leak tightness can only be assured when parts are manufactured precisely to fit the assembly. With our process capabilities, we can provide parts with tight tolerances to meet the most demanding requirements.

Advantages of glass and ceramics in UHV

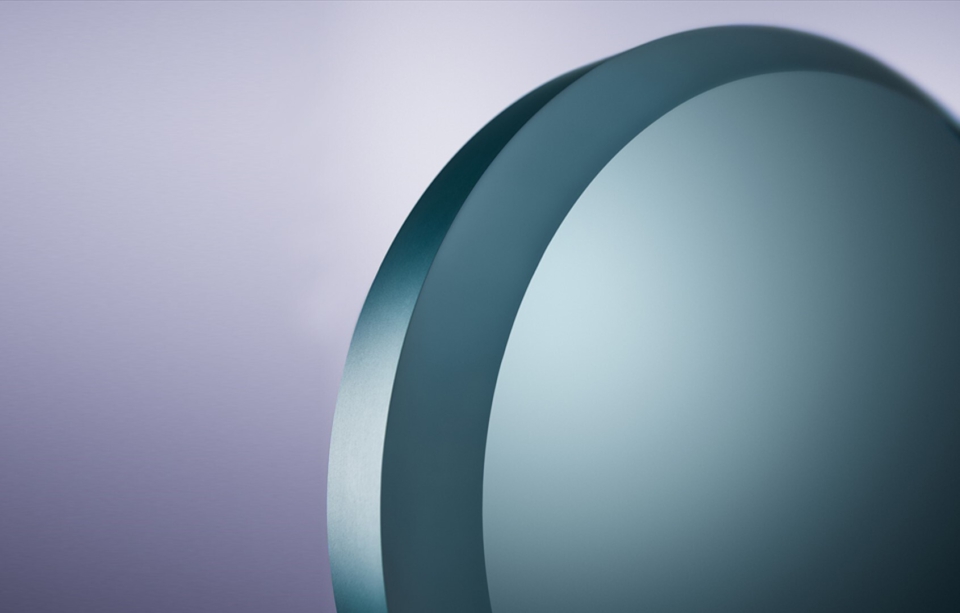

Glass and ceramics have smooth, strong, rigid surfaces, and a very low vapour pressure, which is ideal for vacuum and ultra-high vacuum applications. These materials can withstand far higher temperatures than metal. In addition, most of the metals compared to glass degrade much faster when used in chemical atmospheres like hydrogen. Glass and ceramics are insulating materials for electricity and heat, as metals are conductors. This is why these materials are essential for high voltage feedthroughs.

Contamination control is the key

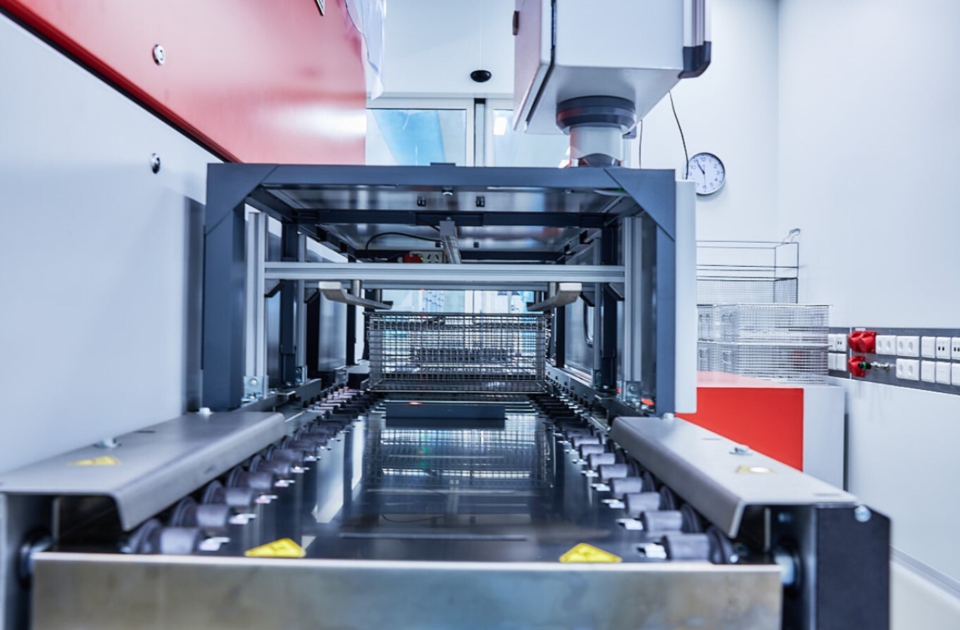

Only precision engineering and constant innovation of processes are not enough. Pre-treatment (baking) and after-treatment (cleaning and packaging) of the systems’ surfaces are vital in the production process. Meanwhile, the whole process chain has to be controlled in order to meet all criteria. This is why we implement contamination control strategies, like visual and microscopic inspection steps and cleanroom monitoring measurements throughout the stages of manufacturing. This allows us to easily identify, find and tackle cleanliness challenges. Within the three large in-house cleanrooms with six different cleaning lines, we combine various cleaning methods such as automatic liquid cleaning and vapour cleaning in order to meet the desired specifications. Due to our vast experience in handling glass, we know how to clean delicate and brittle objects that can be easily damaged.

Typical solutions

- Ultra-high vacuum feedthroughs

- Rupture disks

- Glass barrier plugs

- Pressure disks