Micro-Assemblies

LouwersHanique can co-design and manufacture specific 3D structures in glass and ceramics with the smallest possible geometries.

Pushing the boundaries of what is possible

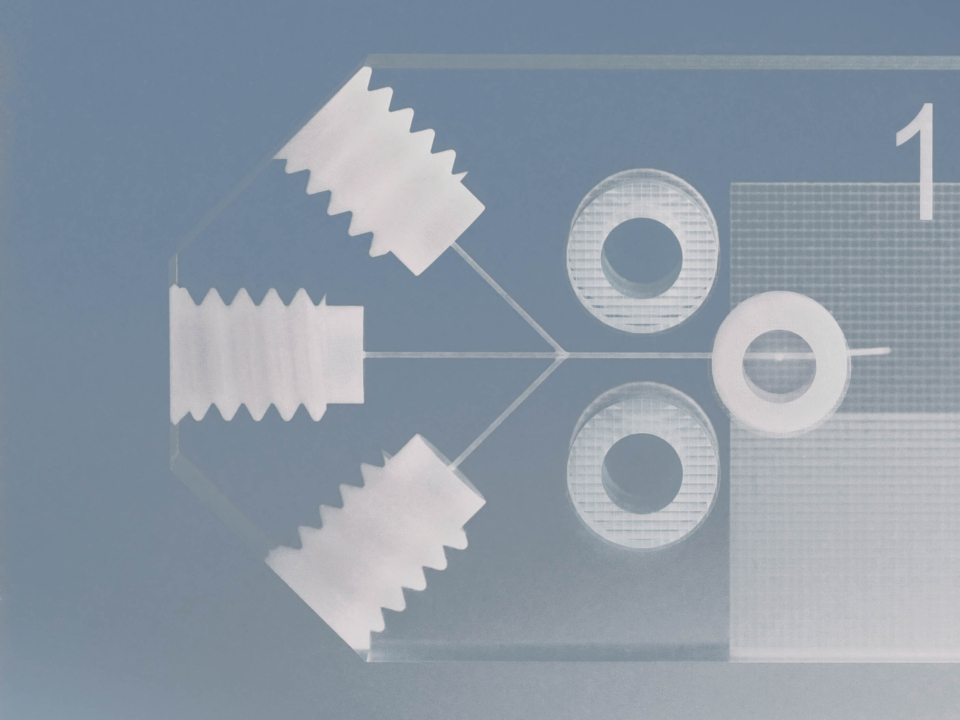

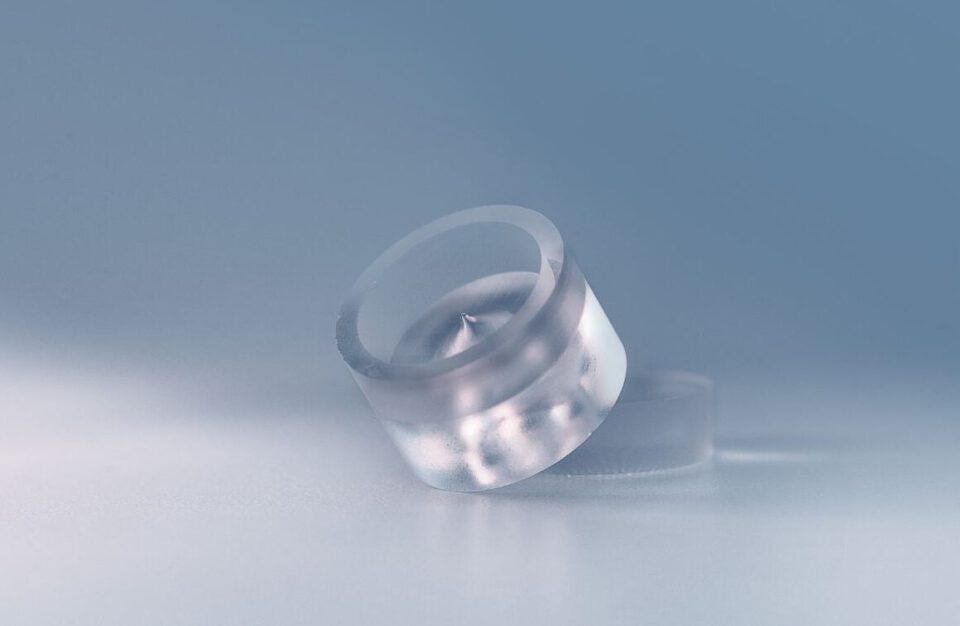

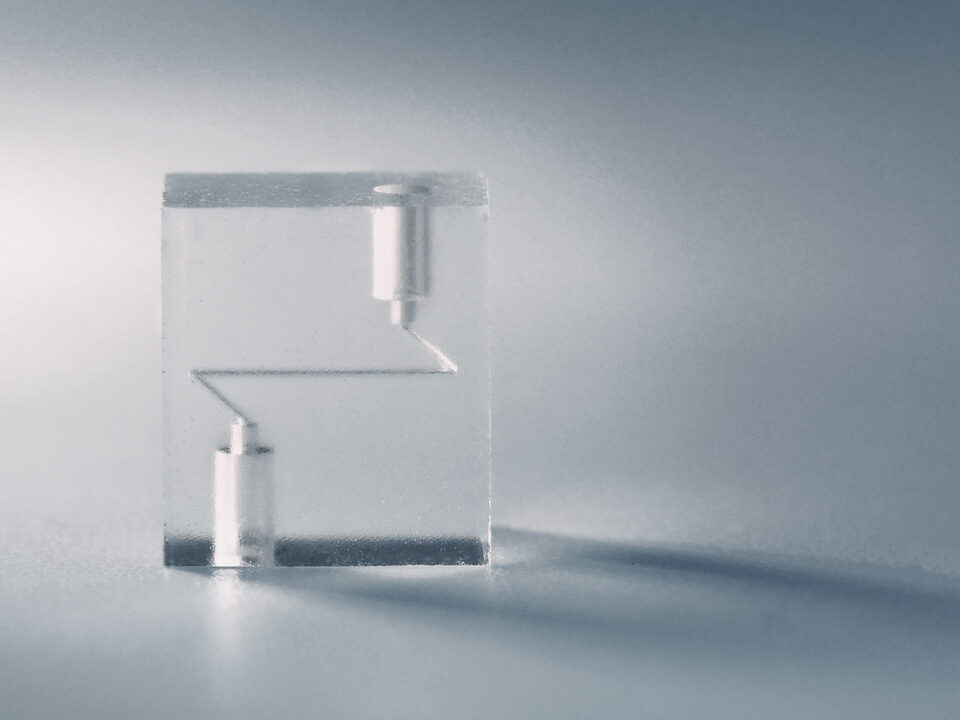

Ever since the first Lab-on-a-Chip developments, micro-assemblies have become an innovation focal point. As technology evolves, various industries are in a constant need to create smaller components than ever before. Nowadays, we are increasingly surrounded by micro-lenses, filters, prisms, and couplers to a whole host of unique 3D micro-structures and micro-fluidic channels. All of these are brought together in extremely small dimensions creating micro assemblies such as multiple sensor types, column parts and (sub)assemblies for e-beam systems.

Zooming in on system miniaturization

As Industry 4.0 and IoT developments push technical innovation, complete systems are being miniaturized. By building complex 3D microstructures on a range of materials, designers can let their imaginations run free when it comes to visualizing the latest high-tech products. Miniaturized devices enlarge the design space, reduce the form factor, accelerate quicker, have higher dimensional stability, and encounter less distortion and vibration which all lead to an improved user experience. The drive for miniaturization is visible across a range of high tech markets such as the MedTech market where there is a need for smaller endoscopes. Miniaturization of medical components results in improved patient care and reduced post-surgical trauma.

In-depth knowledge of various micro-assembly techniques

In order to produce smaller components for our customers, we are continuously pushing the limits of production technology. We combine our knowledge of materials and traditional production technologies to meet the highest standards when manufacturing micro components for micro assemblies. This requires us to continuously develop new automated production, cleaning, and packaging processes.

Combining traditional and cutting-edge processes

Creating micro-structures is only possible by using both traditional and cutting-edge processes including 3D printing, Selective Laser Etching structuring and Filament cutting. We not only produce numerous micro-assemblies but have been helping develop some of the cutting-edge processes needed to realize them. Combining these technologies and processes under one roof ensures we can consistently meet the exact tolerances demanded by our customers. These micro-assemblies are often used in critical applications in industries ranging from semiconductors to medical devices where failure is not an option.

Typical solutions

- Optical and conductive coatings

- 3D microstructures, micro-channels, mixers

- Housings, glass encapsulation, process components

Typical components

- Gas sensors, gas chromatography, oxygen sensors, optical sensors, lithography sensors

- Reticles parts, pellicle components, support rings, micro-lenses

- Endoscopy parts, cochlear implants, microfluidic devices