Medical and Biotechnology

Precise micro-assemblies and optical 3D glass components help medical and biotechnology companies miniaturize and innovate medical devices.

Making life better with with medical glass components

In recent years there has been significant growth in advanced technology for medical and biotechnology applications – from personalized medicine to small portable or even embedded medical devices providing 24/7 monitoring. Medical grade devices need to deliver the highest possible accuracy and must meet strict regulatory requirements. As a customer-driven supplier in machining glass and ceramics, LouwersHanique helps leading medical device manufacturers, OEMs, and research-driven start-ups solve product and design challenges. We understand what it takes to develop and produce unique, ground-breaking solutions, from highly precise medical components used in endoscopy to photomasks for X-ray technology.

See micro-assemblies

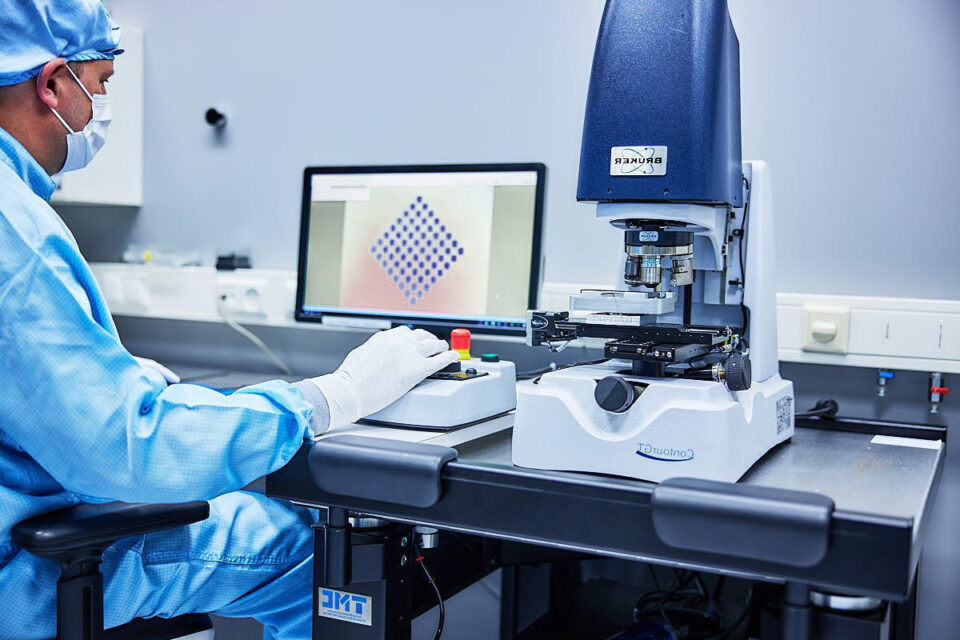

Consistency and traceability

The pathway from concept to product approval can be a lengthy one in the world of medical technology. The slightest deviation can have a major impact on a product. Thorough testing and scientific research determine the pathway to final product approval. So having a proven production partner, capable of consistently delivering the exact requirements and full traceability, is crucial.

Pushing boundaries and miniaturization

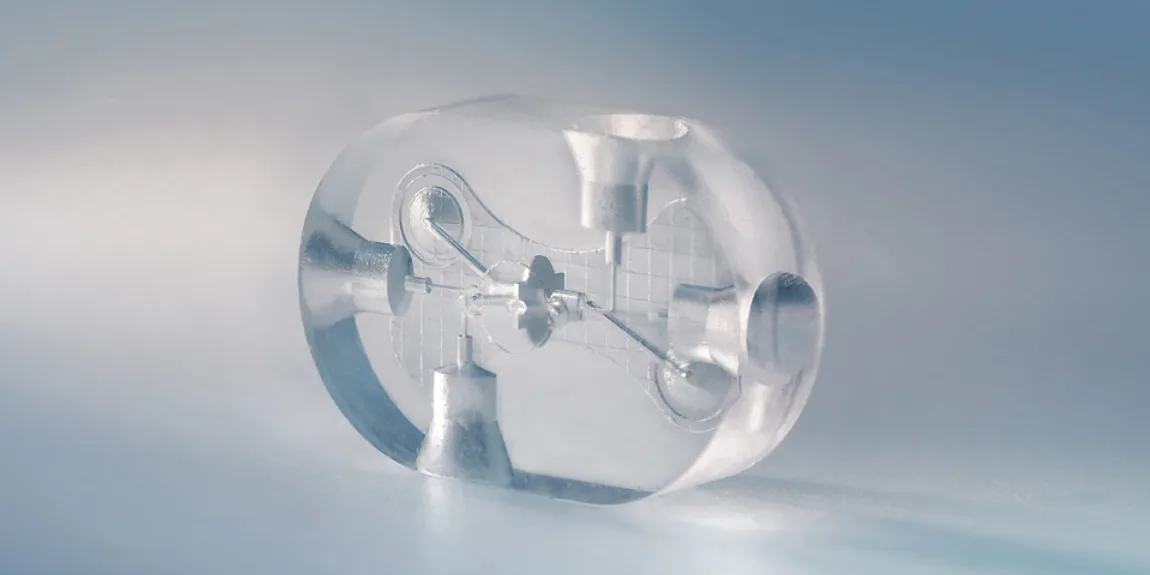

LouwersHanique has been working with OEMs and leading medical technology companies, as well as university and research-driven start-ups. Typically, we are involved from a very early phase of product design. We understand that medical-grade products and material specifications are of utmost importance, particularly when it comes to traceability, quality, and consistency. Miniaturized devices enlarge the design space, reduce the form factor, accelerate quicker, have higher dimensional stability, and encounter less distortion and vibration. This all leads to an improved user experience regardless of the type of medical application. The need to push the boundaries of miniaturization is the result of the increased need to predict, prevent, and monitor requires smart integration of electronics, sensors, and fibers in medical devices or implants. Regardless of whether that is for the micro-assemblies used in Lab-on-Chip developments or for smart implants.

Smart integration of electronics

There is a strong driver to reduce pressure on healthcare and in particular the length of stays. Personalized medicine and smarter medical devices are one of the means that will enable more efficient and improved care. The increasing need to predict, prevent and consistently monitor patients requires smart integration of electronics, sensors and fibers in medical devices or implants. Precision glass is a safe and durable material that can be used to hermetically encapsulate electronics in medical devices.

Typical applications

- Medical Laser Solutions

CO2 laser tubes, laser parts - 3D Micro-Assemblies

3D microstructures, microfluidics, channels, mixers, endoscopy part - Medical Implants

Medical housing implants, hermetic encapsulation, bioceramics, 3D microparts - X-rays & Nuclear Medicine

Glass substrates & columns, nuclear ampules, cartridges, X-ray and imaging components