Co-Development

Understand the possibilities and realize the potential of your design and NPIs s in glass and ceramics with our full R&D and engineering support.

Exceeding your expectations

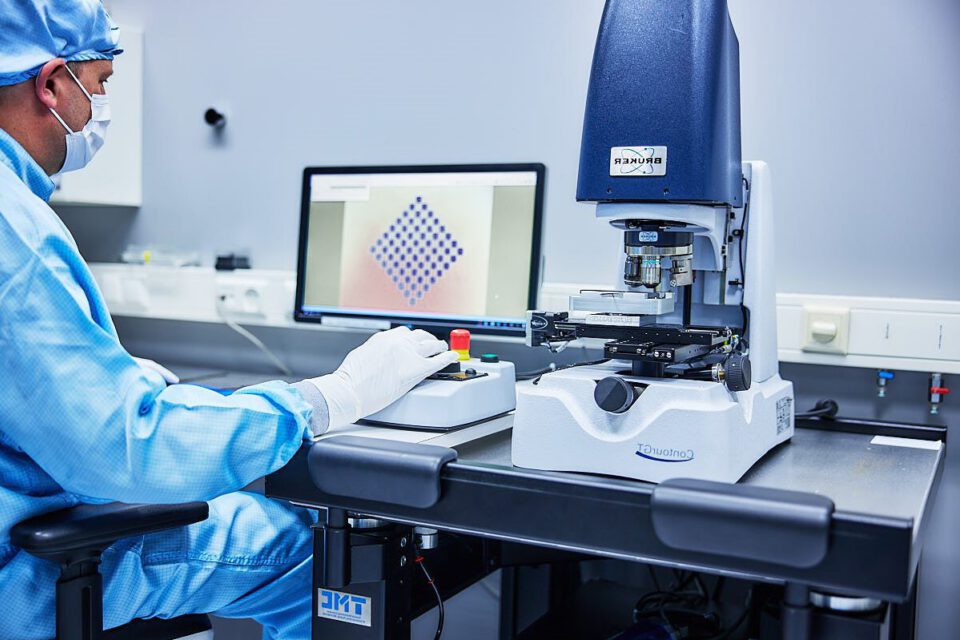

Cutting-edge glass and ceramic technologies have advanced significantly in the last few years. Understanding the possibilities and processes involved is effectively a full-time job. At LouwersHanique we have the capabilities, knowledge and processes under one roof, and continually invest to stay at the forefront of technology. That gives us an insight into just how far we can push various materials to meet your needs.

Get in touch today

Your co-development partner

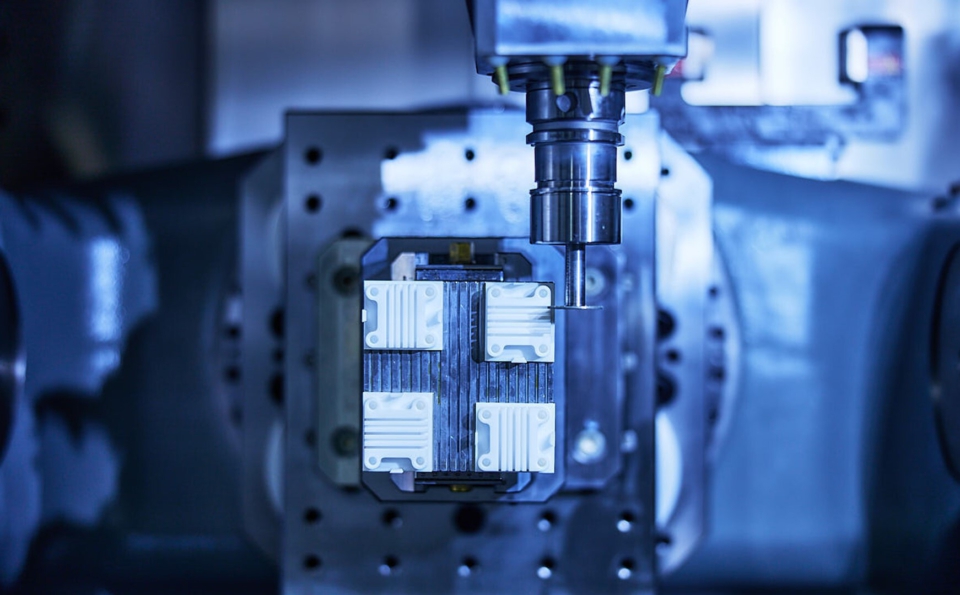

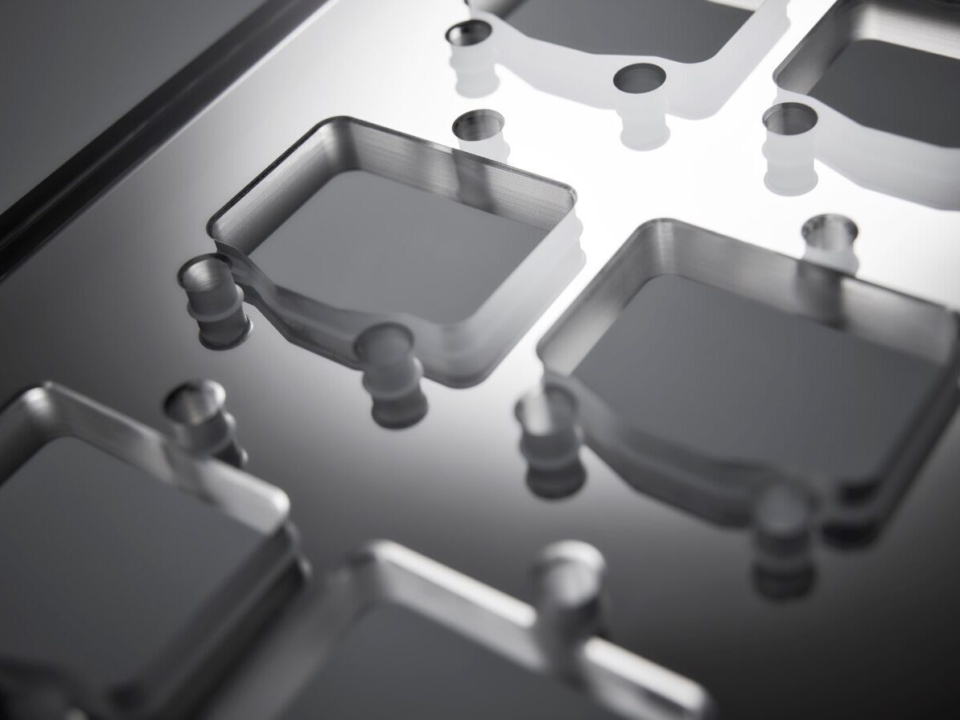

Whether it is thermal shaping, mechanical processing, bonding or making 3D microstructures, LouwersHanique provides a total solution. This means working alongside you on your design and supporting with material sourcing and logistics. In fact, we are much more than just being a proven precision engineering production facility. LouwersHanique offers full R&D and engineering support during all the phases of the product's life cycle. From concept development up to and including series production and re-engineering, we can act as a seamless extension to your engineering team.

Driven by your ambition

‘Driven by your ambition' is our company motto. It stands for our passion and enthusiasm when working together with our customers to achieve unique total solutions that deliver a real competitive edge. LouwersHanique is a trusted partner in semiconductor, medical, and analytical markets, with extensive knowledge and experience in glass, ceramics, and all types of special material combinations. All this while keeping the continuously increasing demands in the fields of tolerances, quality, and reliability in mind.

Featured services

- Translating drawings and dimensions into realistic production specifications (Design for Manufacturing)

- Selecting materials to fit specific optical, thermal and chemically stable properties

- Developing and optimizing dedicated production processes based on Copy Exact principles (Design for Costing)

Typical materials

- Glass (Borosilicate, Zerodur®, soda lime silica)

- Quartz (Fused silica)

- Macor®

- Aluminium oxide

- Stainless steel (316L & 304)

- Nickel alloy (Hastelloy®)

- Aluminium (5083 & 6082)

Typical material combinations

- Technical glass to glass bonding

- Borosilicate glass to ceramics bonding

- Glass to metal bonding

- Ceramics to ceramics bonding

- Ceramics to metal bonding