CNC Machining

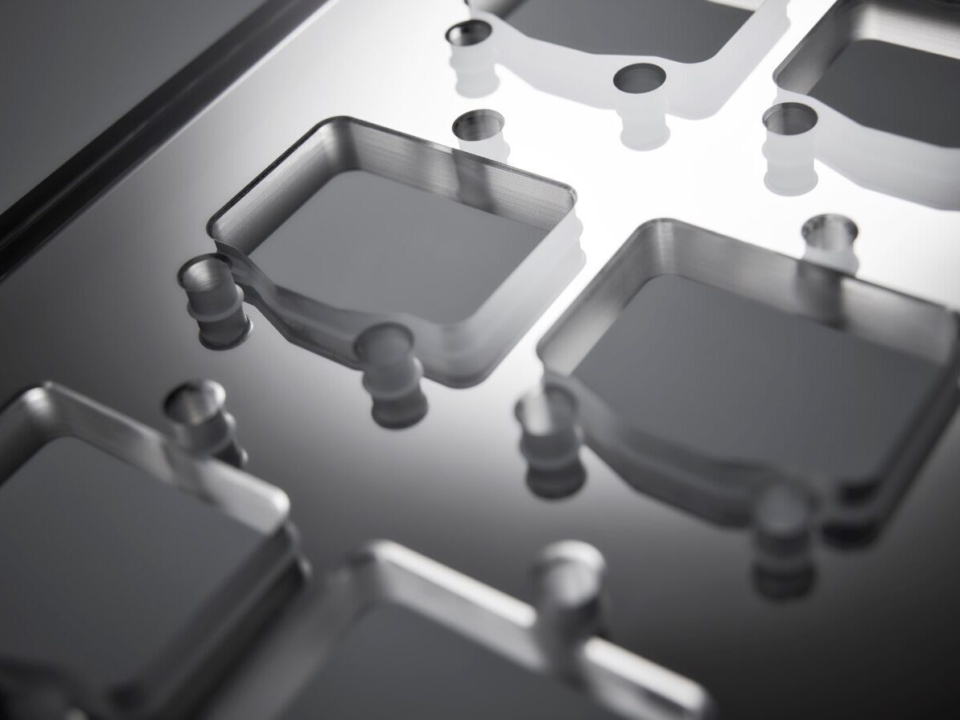

From CNC lathe grinding to 5-axis simultaneous CNC milling, with our mechanical processing capabilities, we handle a wide range of technical glass, ceramics and other brittle materials.

Advanced processing of technical glass and ceramics

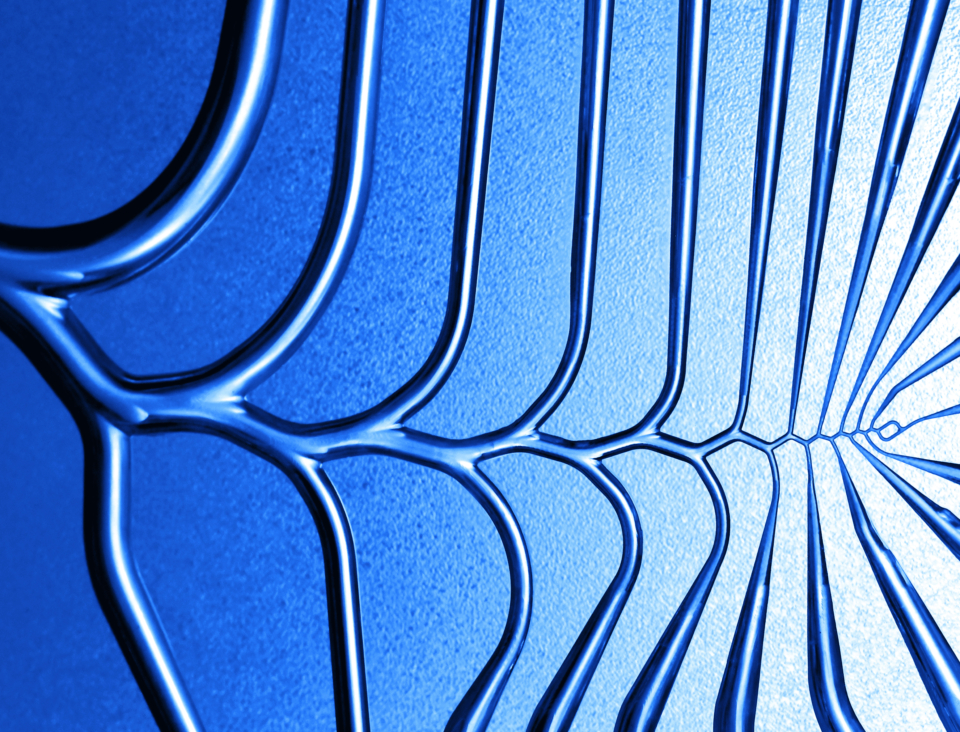

Achieving the right surface finish can be critical to the success of an application. So whether it is precision CNC milling, turning, polishing, lapping or laser processing LouwersHanique has mastered the most advanced technologies. Putting the latest automated CNC technologies in advanced processing of technical glass and ceramics into practice. All our processes are optimized for very accurate, controlled and repetitive processing of a wide variety of technical glass and ceramics materials, ensuring we meet the highest demands in terms of accuracy, purity and finishing.

Get in touch todayMatching processing techniques to your requirements

LouwersHanique provides expert advice to our customers on the right type of material from aluminium oxide to silicon carbide, Macor®, borosilicate glass, soda lime and quartz. Always keeping your application and associated specific requirements in mind. Depending on the requirements and the desired surface roughness an optimum balance of precision CNC and polishing technologies is chosen. For more exact finishes, we rely on precise mechanical machining techniques such as micro-sandblasting, tribofinishing, micro-surface and etching technologies.

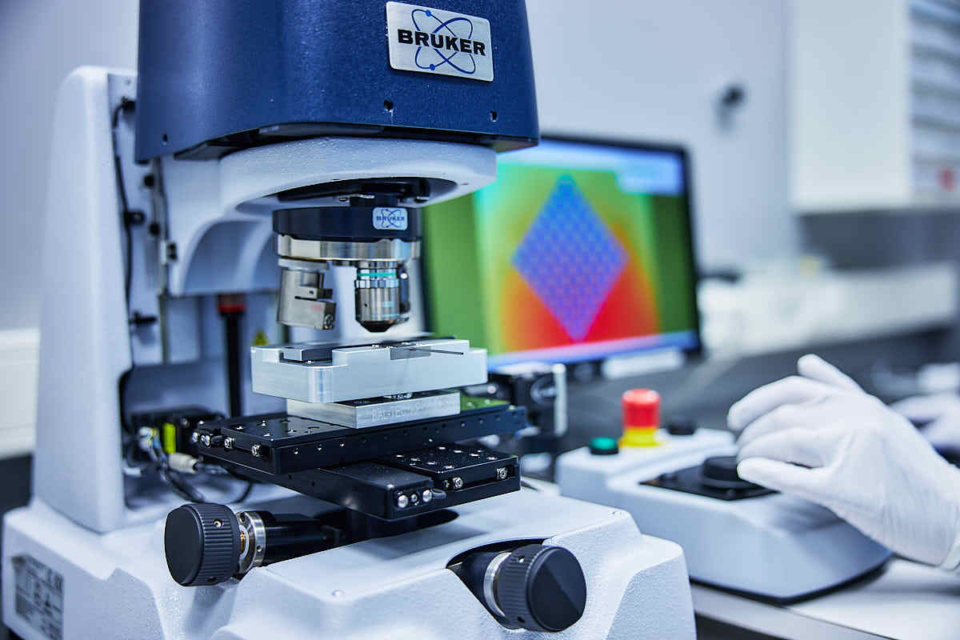

Engineered to the tightest tolerances

At LouwersHanique we can meet the highest requirements when it comes to desired tolerances. We consistently measure and collect data during the manufacturing process (Q in process) rather than solely measuring and monitoring quality at the end of production. All of this is done, to ensure World Class Manufacturing processes that can run 24/7. This is crucial for many of the products we manufacture, including end effectors for wafer handling, wafer carriers and electron beam column components.

Tolerances

- Flatness - 0,003mm

- Cylindercity - 0,002mm

- Perpendicularity - 0,003mm

- Parallelisme - 0,003mm

- Angularity - 0,2°

- Position - 0,002mm

- Circular runout - 0,002mm

- Concentricity - 0,002m

- Symetry - 0,003mm

Featured services

- Precision CNC machining of technical glass and ceramics

- CNC milling: 3 axis and simultaneous 5 axis

- CNC turning: CNC lathe, 3 axis lathe and 5 axis simultaneous lathe

- CNC polishing and CNC lapping

- CNC laser processing and Selective Laser-Induced Etching

- Complementary services

- Micro-sandblasting and tribofinishing

- Statistical data analysis of measurement results (SPC)

- 24/7 automated production

- CAD/ CAM conversion of your 3D CAD models

- Processing of technical ceramics including: aluminium oxide and sapphire [Al2O3], aluminium nitride [AIN], zirconia oxide [ZrO2], silicon carbide [SiC, SiSiC, CVD SiC, C/SiC], silicon nitride [Si3N4], silicon [Si, Six], Macor® and Vitronite

- Processing all technical glass including borosilicate glass, soda lime and quartz

Featured products

- End effectors for wafer handling

- Wafer carriers

- Electron beam column components

- Isolators

- Ceramic feedthroughs

- Heater plates

- Lightguides

Featured materials

- Technical ceramics

- Aluminium oxide [Al2O3] and sapphire [Al2O3]

- Silicon carbide [SiC, SiSiC, CVD SiC, C/SiC]

- Silicon [Si, Six]

- Macor®(glass-ceramics)

- Vitronite

- Aluminium nitride [AIN]

- Zirconia oxide [ZrO2]

- Silicon nitride [Si3N4]

- All technical glass including

- Borosilicate glass

- Soda-lime glass

- Fused silica (quartz)