Semiconductors

We help semiconductor companies to elevate their products and designs with precision glass and ceramics.

Advancing alongside semiconductor innovation

State-of-the-art manufacturing equipment is an obvious requirement for the fabrication of semiconductor components and assemblies. Given our proximity to the Eindhoven-Leuven-Aachen triangle, LouwersHanique has been supporting both equipment makers and IC manufacturers for over 50 years. Providing tailor-made solutions using all our competencies from high-pressure and vacuum components to feedthroughs, mechatronics and micro-assemblies.

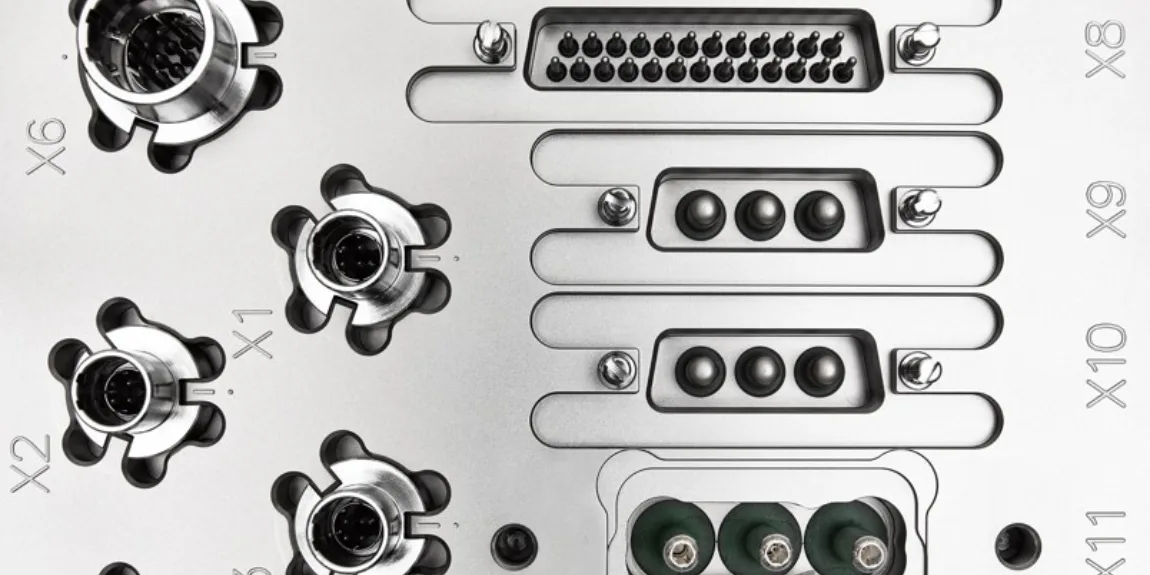

Advanced mechatronics

At the heart of chip manufacturing

Semiconductors and the Eindhoven region are closely linked given the companies that have evolved alongside Philips since semiconductor technology started to take off. With innovations from lithography to integrated photonics, the region is home to some of the most well-known multinationals and cutting-edge SMEs and start-ups within the semiconductor industry.

Tailor-made precision solutions

At LouwersHanique, we are able to manufacture a wide range of customer-specific semiconductor components and subsystems. Using all of our competencies from mechatronics to micro-assemblies we manufacture precision components made of glass, technical ceramics, silicon, and many other brittle materials. The scope of our activities ranges from lithography to electron optics, process equipment and metrology components.

Our automated production processes minimize human errors and are able to achieve the highest consistency in quality. This enables us to meet the tightest tolerances and manufacture high-pressure and vacuum components and complex assemblies such as feedthroughs.

“More than Moore”

From concept development to volume production, LouwersHanique is able to provide a unique total solution for the most challenging applications. Incorporating the latest materials and processes to help the industry as it strives to achieve the next technology node and transition to the “More than Moore” processes and products that will enable the 4th Industrial Revolution (Industry 4.0). As the industry keeps evolving and striving for perfection, so do we along with our clients.

Typical applications

- Electron Optics

E-Beam column assemblies, lenses, high voltage feedthroughs, isolators, lights guides - Lithography

Sensor parts, lithography sensors, vacuum feedthroughs, pellicle components - Metrology

Chucks, wafer handling, shims, insulators, reticle parts, diffusers - Process Equipment

Mixers, gas dividers, showerheads, microfluidics, nozzles, carriers

Typical materials

- Glass (Borosilicate, Zerodur®, soda lime silica)

- Quartz (Fused silica)

- Macor®

- Aluminium oxide

- Stainless steel (316L & 304)

- Nickel alloy (Hastelloy®)

- Aluminium (5083 & 6082)