Ultra-High Vacuum Cleaning

Working with semiconductor, biotechnology and pharmaceutical customers requires us to maintain extremely clean processes and working environments.

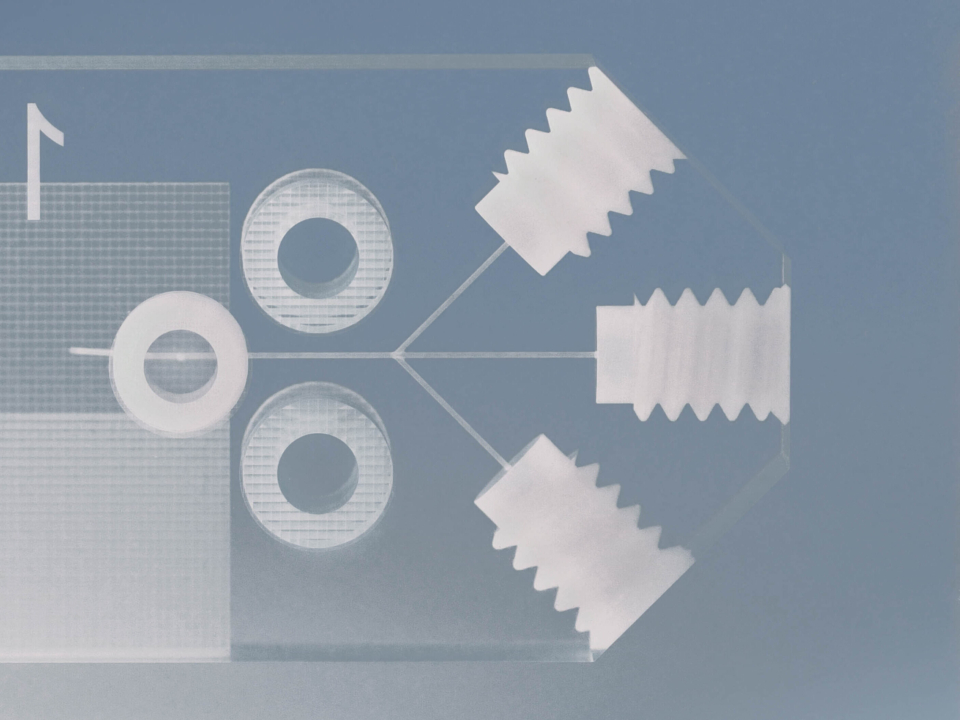

Specialized cleaning of glass, ceramic, and metal components

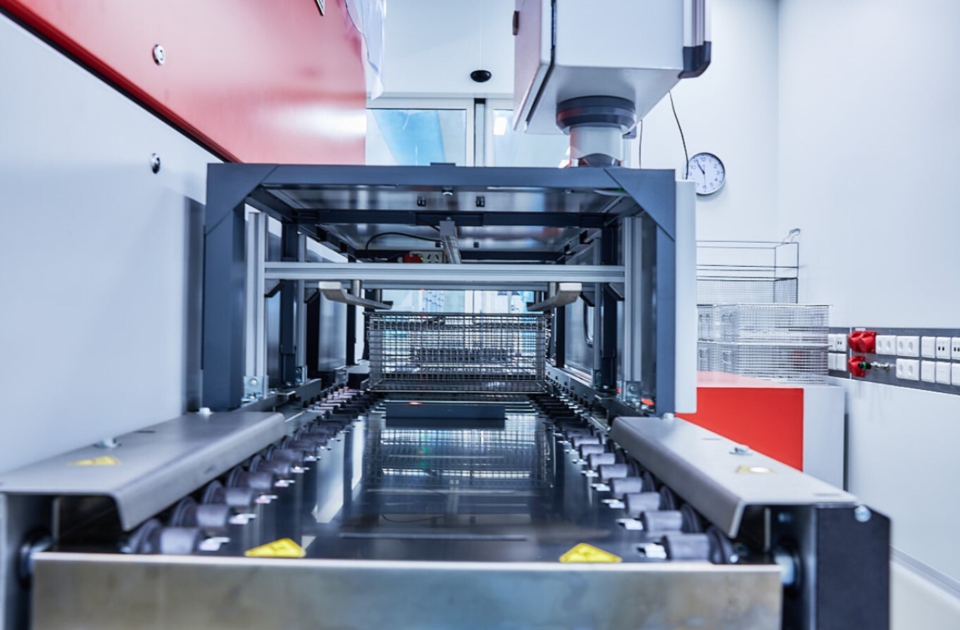

With automatic cleaning lines, automated vacuum bake-out and our extensive experience in manual cleaning with various chemicals and soaps, LouwersHanique provides a range of high-tech cleaning options. We have several in-house cleanrooms, where individual components made of a variety of material combinations can be cleaned up to grades 4 and 2. Subsequently, they can be shipped for possible further assembly. All of this is done at the highest standard, giving you peace of mind enabling you to focus on your core activities.

Get in touch today

Spotless cleaning processes

At LouwersHanique we take the final cleanliness requirements into consideration at the beginning of the production process. We begin by making use of special machining fluid that can be fully removed by the end of the production process. This is done alongside multiple cleaning stages, to ensure that no dried-in contamination remains on the surface of the final product.

In the field of cleanroom grade cleaning, qualification, and packaging, LouwersHanique boasts extensive Class 1000 (ISO 5) facilities. This allows for proficiency in UHV (Grade 2) cleaning processes for vacuum cleanliness as well as Residual Gas Analysis (RGA) qualification options.

Contamination control

To achieve outstanding results, we implement various contamination control strategies throughout the stages of manufacturing. We conduct visual and microscopic inspection steps and cleanroom monitoring measurements throughout the stages of manufacturing. Moreover, all measurement methods such as helium leak test, electrical conductivity measurements, optical microscope, and interferometer measurements are conducted in a cleanroom to eliminate all possible contamination sources. This allows us to easily identify, find and tackle cleanliness challenges. Within the three in-house cleanrooms with six different cleaning lines, we combine various cleaning methods such as automatic liquid cleaning and solvent vapour cleaning in order to meet the desired specifications.

Variety of materials

Due to our vast experience in handling glass, we know how to clean delicate and brittle objects that can be easily damaged. This in combination with our extensive cleaning facilities enables us to clean a wide range of materials and combinations thereof. Such as various types of glass, macor, aluminium oxide, stainless steel (316L & 304), Hastelloy® (nickel alloy), and aluminium (5083 & 6082).

Featured services

- Cleanroom ISO grade 5 &7

- Ultra-High Vacuum cleaning

- Automatic vacuum bake-out

- Automated cleaning lines

- Cleanroom packaging and labelling

- Various in-house measurements

Featured materials

- Glass (Borosilicate, Zerodur®, soda-lime silica)

- Quartz (Fused silica)

- Macor®

- Aluminium oxide

- Stainless steel (316L & 304)

- Nickel alloy (Hastelloy®)

- Aluminium (5083 & 6082)