Mechatronics

Drawing on the unique material properties of glass and ceramics, we help you with your mechatronic design challenges.

The cornerstone of precision and performance

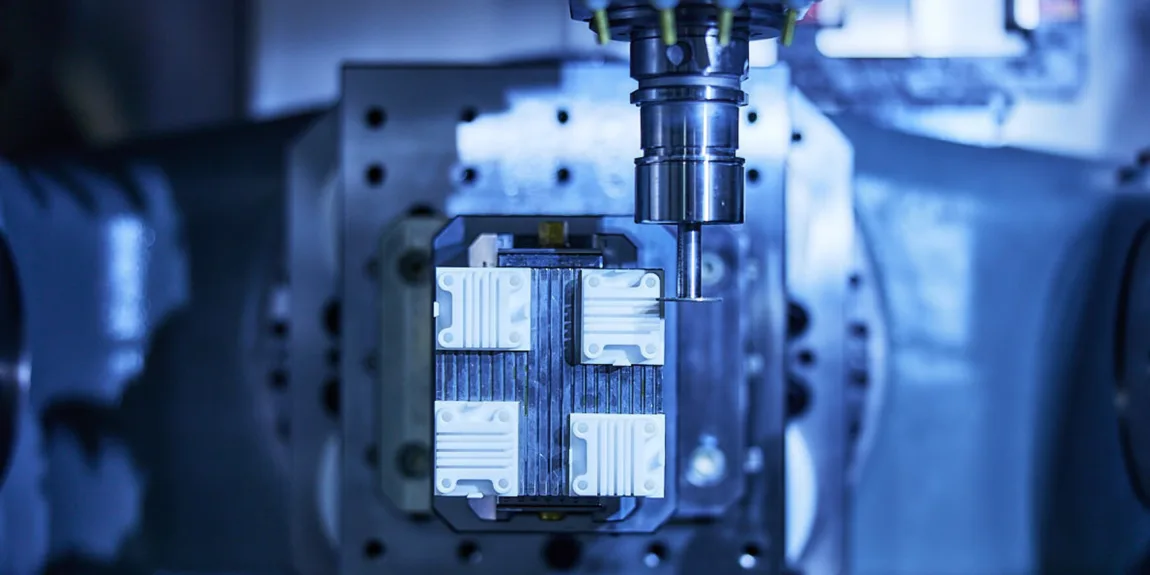

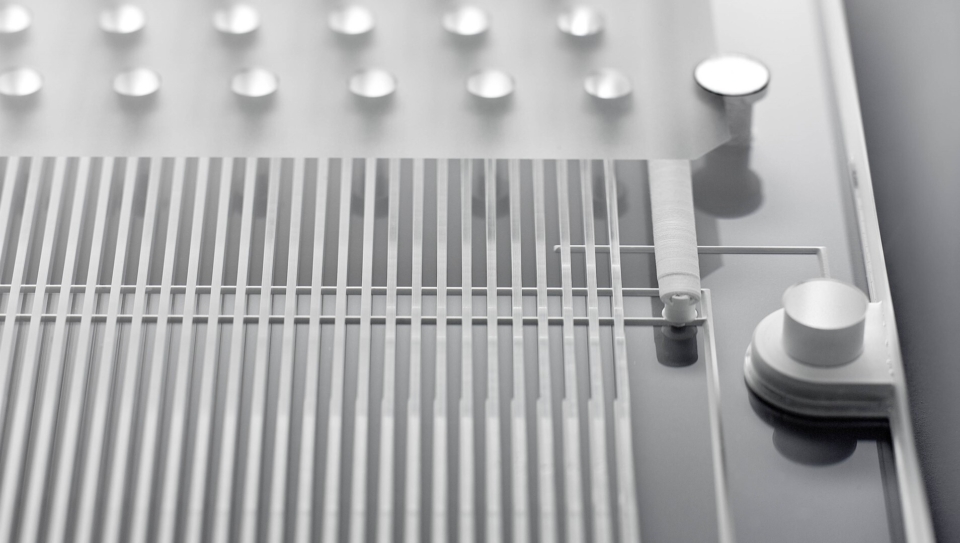

When it comes to modern industrial equipment, advanced mechatronic assemblies have become the cornerstone of precision and performance. For many components, metal tends to be the material of choice. However, depending on the required material properties, such as electrical insulation, low thermal expansion or minimal outgassing, then glass and ceramics play an important role. LouwersHanique supplies custom glass and ceramic components for advanced mechatronic assemblies used in various markets like the MedTech and semiconductor market.

A strong focus on high-end mechatronics

When it comes to designing high-end mechatronic modules and (sub)systems, customers often have a clear understanding of the design challenge and their needs. But given more traditional material options do not fit the requirements, they are often unsure of the possibilities of glass and ceramics. LouwersHanique not only intimately understands the properties of these materials but knows how they can be applied to meet the standards required for various applications. And many of our products and solutions are embedded in active systems that have been operating for more than 30 years.

Combining expertise to innovate

Early involvement and co-development are the keys to success. Our dedicated development and engineering department can support customers in selecting the best material for their application as well as helping to source the raw materials and product-specific packaging. In fact, LouwersHanique can even manage the complete supply chain, freeing you up to focus on your core business.

Typical solutions

- Chucks, wafer handling, end effectors, reticles parts

- Box assembly, low expansion frames

- Carriers (zerodur, ULE), isolators

- Mounting blocks, shimms, covers

- Glass bonded e-beam assemblies

Featured materials

- Glass (Borosilicate, Zerodur®, soda lime silica)

- Quartz (Fused silica)

- Macor®

- Aluminium oxide

- Stainless steel (316L & 304)

- Nickel alloy (Hastelloy®)

- Aluminium (5083 & 6082)