Industrial and Scientific Glassware

The latest material processing technologies for industrial and scientific glassware applications.

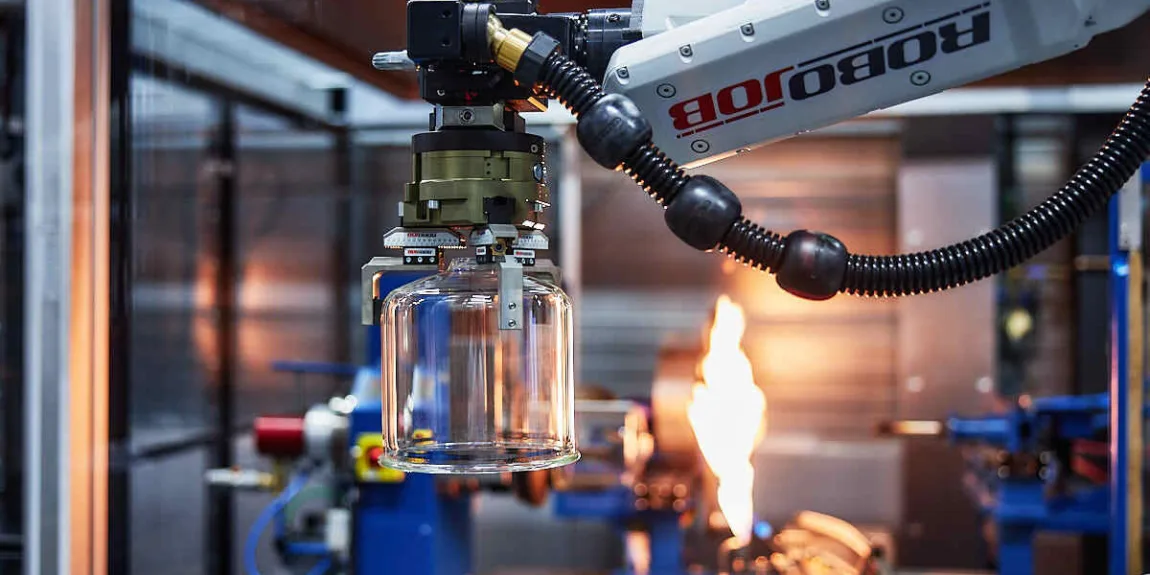

The advantages of automated production processes

Glassware for industrial, optical, and scientific applications has changed significantly in the last 50 years. The production processes at LouwersHanique have changed as well, shifting from traditional craftmanship to automated production processes ensuring copy exact capabilities. This allows us to consistently manufacture industrial glassware that meets the specifications required by our customers. We are able to meet the most advanced requirements for a variety of applications from titration vessels and bioreactors to nuclear ampoules and laser tubes.

Custom glassware and glass components

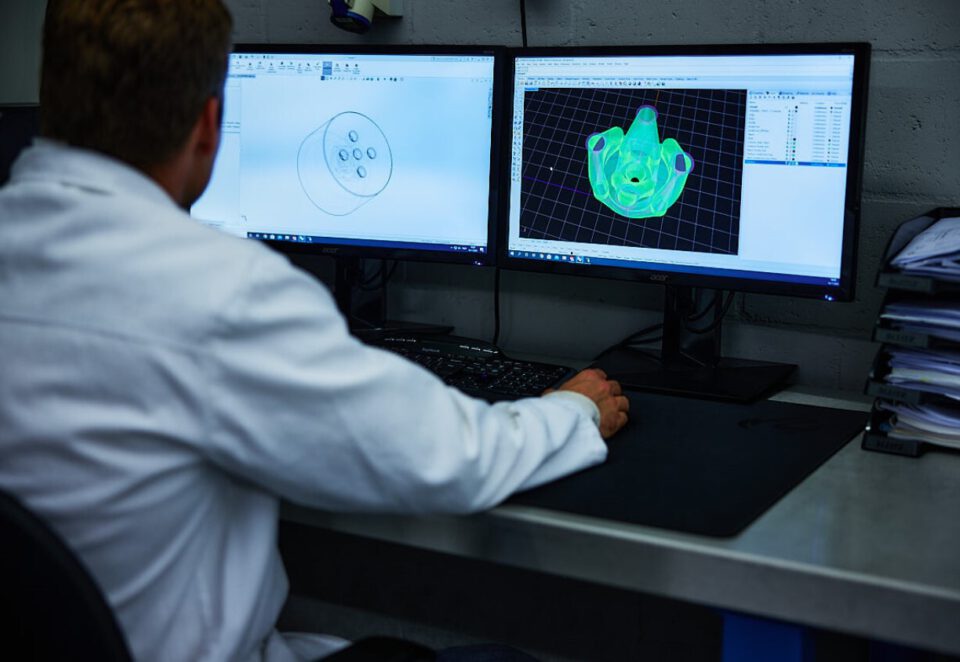

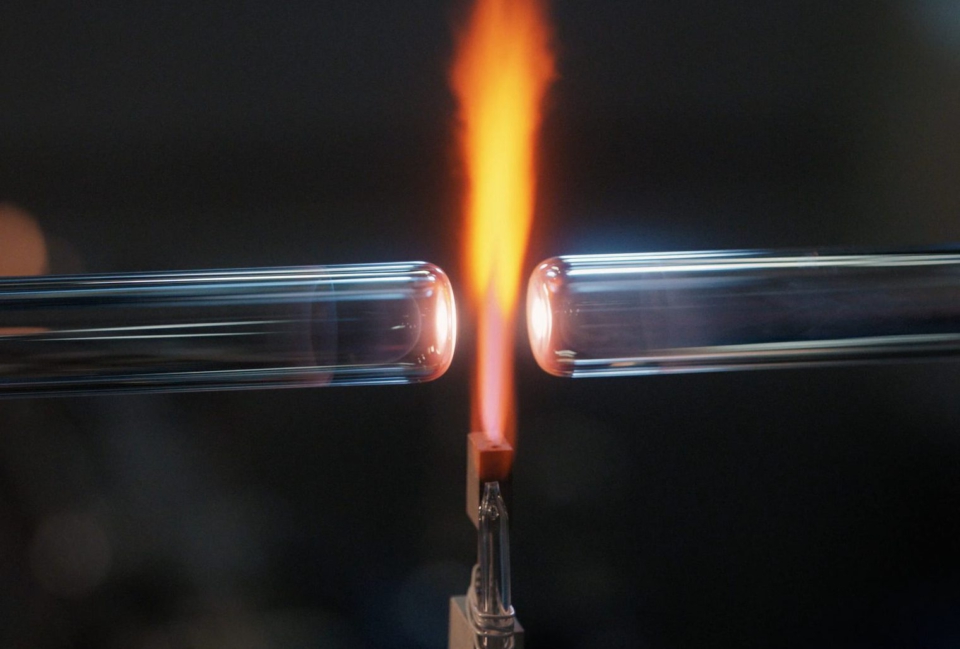

When people think of industrial and scientific glassware, it often conjures up images of laboratory technicians mixing liquids together using different glass beakers. While there remains a need for traditional ‘catalog’ glassware, many applications require customization and higher levels of accuracy, quality and robustness. To enable these individual adjustments, we combine the processing of borosilicate glass, quartz glass, Zerodur, and soda-lime glass with thermal processing, laser processing, and various CNC processing methods.

Continuous development in processing methods and automation

For ages, glass has been a hand-shaped material, that is prone to human errors and inconsistencies. At LouwersHanique machines work alongside people to deliver precise glass and quartz products with a consistent quality every single time. We utilize statistical process–controlled methods and fully automated production cells. This is particularly important to continuously achieve the same results when it comes to the thermal processing of glass and quartz.

Experience and co-development expertise

With more than 70 years of experience, we have built up specific knowledge and understanding of the properties of glass materials and production methods. We work closely with our customers to co-develop and manufacture complex glass components. Such applications often include measurement and pharmaceutical process equipment as well as analytical instruments. Our solutions help you realize a competitive advantage for your product or system.

Typical components

- Glass reactor vessels, titration vessels, irradiation vessels

- Bioreactors, nuclear ampoules, cartridges, barrels, filling bells

- Glass columns, injectors, glass inserts, glass carriers, measuring cells

- Quartz tubes, lamp tubes, CO2 laser tubes, ionization tubes, cuvettes

- Light guides, quartz windows

Typical materials

- Soda-lime-silica glass

- Borosilicate glass

- Quartz glass

- Zerodur®