High-tech assembly

We offer a range of joining processes that deliver extremely high quality and are suitable for advanced precision assemblies and sub(systems).

Joining techniques for high precision components

After thermal, mechanical or laser processing of sensors and feedthroughs, LouwersHanique can arrange for precision assembly of glass or ceramic components. Our expertise is centered around joining glass-glass, glass-ceramic, glass-metal, ceramic-ceramics, ceramics-metal and specifically reticles-optical elements. This can be achieved through various joining techniques, such as precision glueing and high-quality glass joining.

Get in touch today

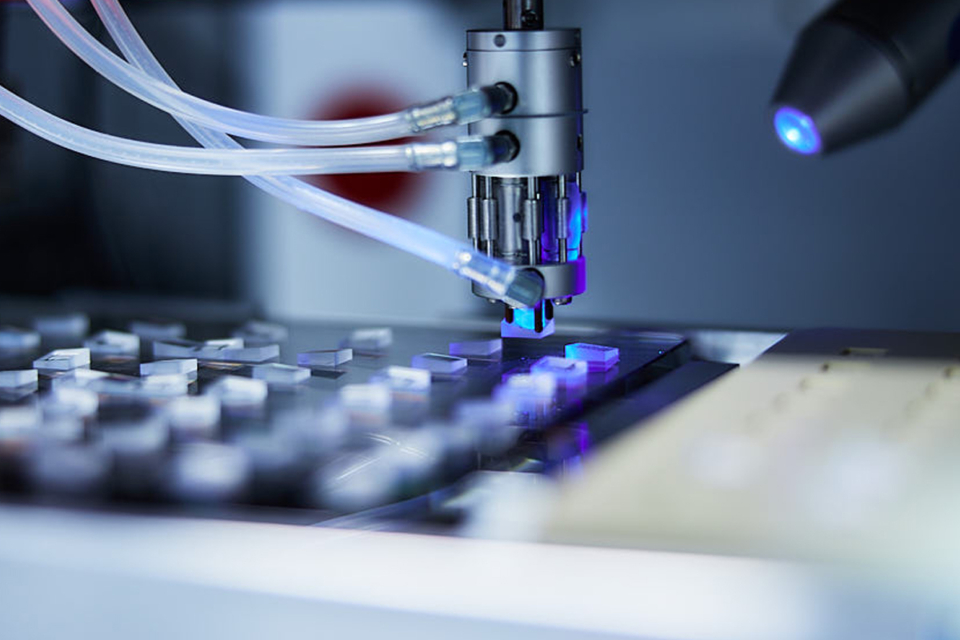

Precision joining technology

Many dissimilar materials and parts can be joined together through the application of various joining techniques. Depending on the final component, we assemble products and modules that meet the highest demands of ultra-high and ultra-clean vacuum applications. Therefore, it is essential to perform these processes in high level and critical cleanroom assembly environments. This is essential for many of the semiconductor components we produce but can be applied to any product.

Optical assembly of transparent materials

LouwersHanique’s optical assembly solutions for transparent materials provide submicron precision across a wide range of applications, particularly in the photonics market. Through the use of passive and active alignment, we enable complex micro-assembly with advanced techniques such as Selective Laser-Induced Etching (SLE), CNC machining, and high-precision polishing.

Our capabilities include 6 degrees of freedom alignment, ultra-fine glue placement below 2 micrograms, and customizable active alignment systems. Gap measurement technology ensures perfect alignment, while automated assembly boosts scalability. All processes are carried out in ISO 7 cleanroom conditions, guaranteeing consistent, high-quality results for the most demanding applications

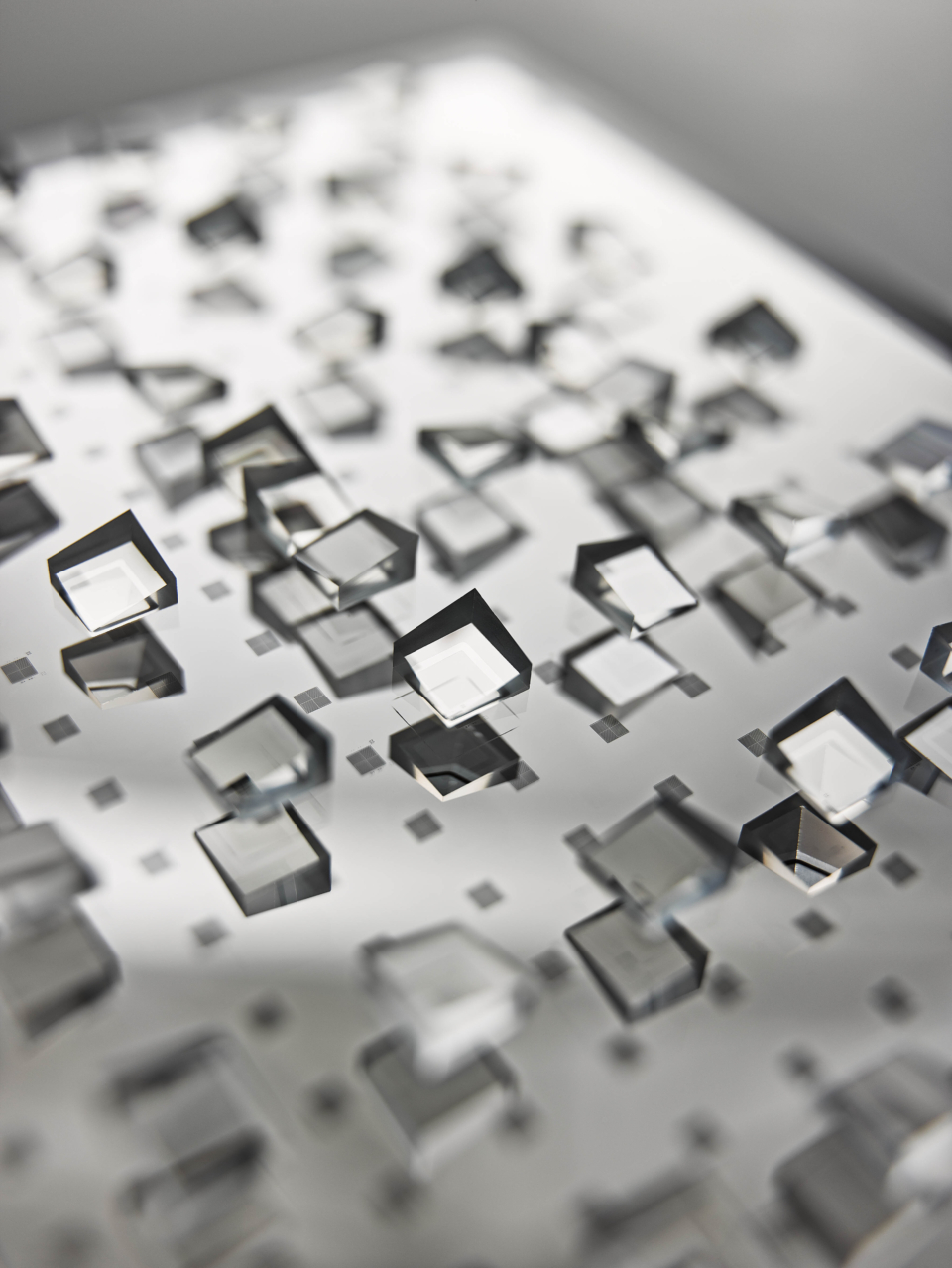

Glass-to-metal connections: Ideal for feedthroughs

Direct glass-metal joinings are ideal for producing modular and customized feedthroughs. Many connector types are available, such as sub-D, Harting, LEMO and optical fiber. Almost any combination is possible from low-noise coaxial to high power, high voltage, optical and more. These combinations can be supplied according to the desired preferences on a customer-specific basis. The process allows for unprecedented integration and a unique high-performance functionality while ensuring there are no unnecessary connections and therefore no virtual leaks.

A wide range of metals and alloys are available tungsten, molybdenum, aluminium, titanium, platinum, fernico, nickel and stainless steel. The result is the ultimate feedthrough, with respect to outgassing and purity as well as functionality and reliability.

Featured services

- Precision glueing

- Submicron precision optical assembly

- High-quality glass joining

- Mechanical assembly based on (monolithic) feedthroughs

- Precision welding

- Brazing

- Submicron precision optical assembly

- Active and passive alignment

Featured material combinations

- Technical glass to glass bonding

- Borosilicate glass to ceramics bonding

- Glass to metal bonding

- Ceramics to ceramics bonding

- Ceramics to metal bonding