Industrial and Energy

High-pressure and vacuum components for the industrial & energy market that can withstand the most extreme conditions in harsh environments.

Exceptionally robust and safe critical components

As is the case with many vital industries, the industrial and energy market is undergoing a major transition with a strong driver for technologies that positively impact the environment. Yet many industrial and energy processes typically involve operating under extreme environmental conditions and pressures. So critical components need to be exceptionally robust and safe.

Working at the extremes

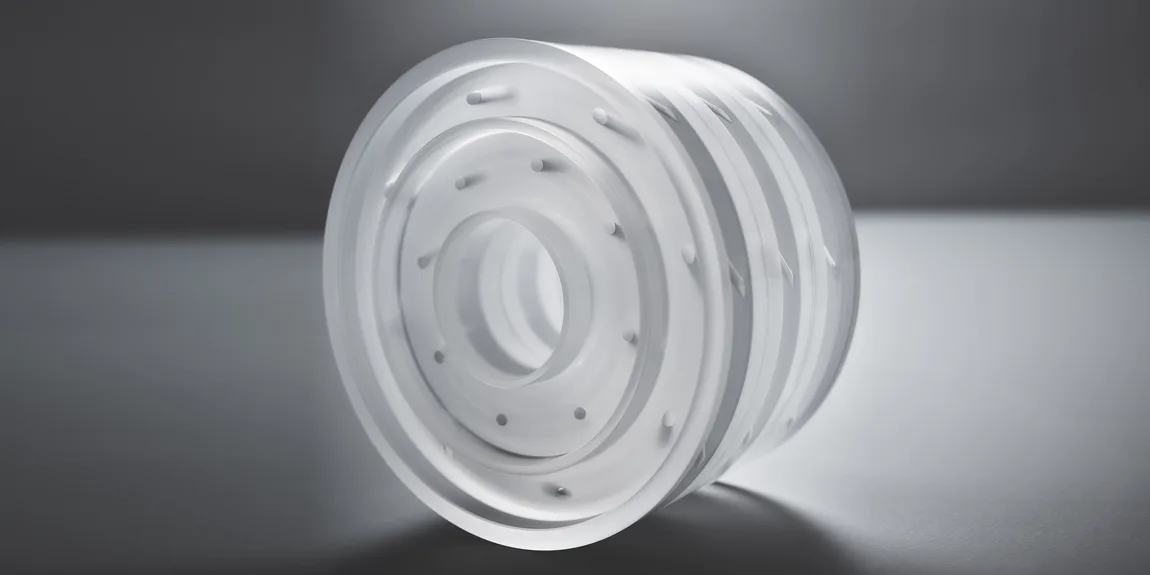

Glass and ceramic seals and rupture disks are commonly used in pressure vessels and industrial equipment to safeguard pressure or vacuum conditions. Our glass to metal feedthrough technology enables advanced measurements at a high vacuum or in high-pressure scenarios. Industrial glass to metal feedthroughs can for example be deployed in offshore environments or in other harsh industrial environments. For industrial applications, the durability and resistance to wear are extremely critical, as repairs or replacements often result in an operational shut-down. LouwersHanique takes pride in the feedthroughs that were produced 20 years ago and are still fully operational.

Cleaner air and surfaces

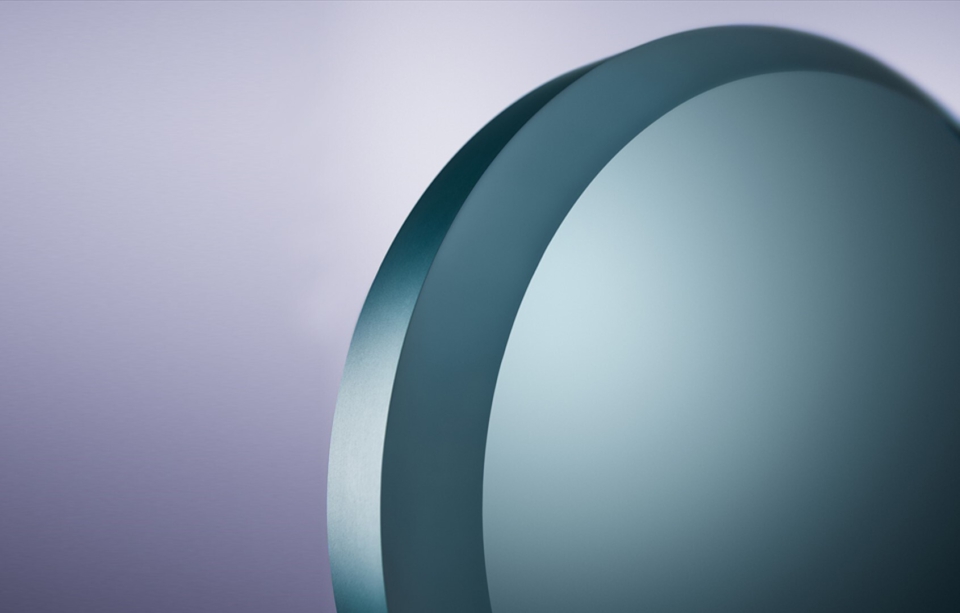

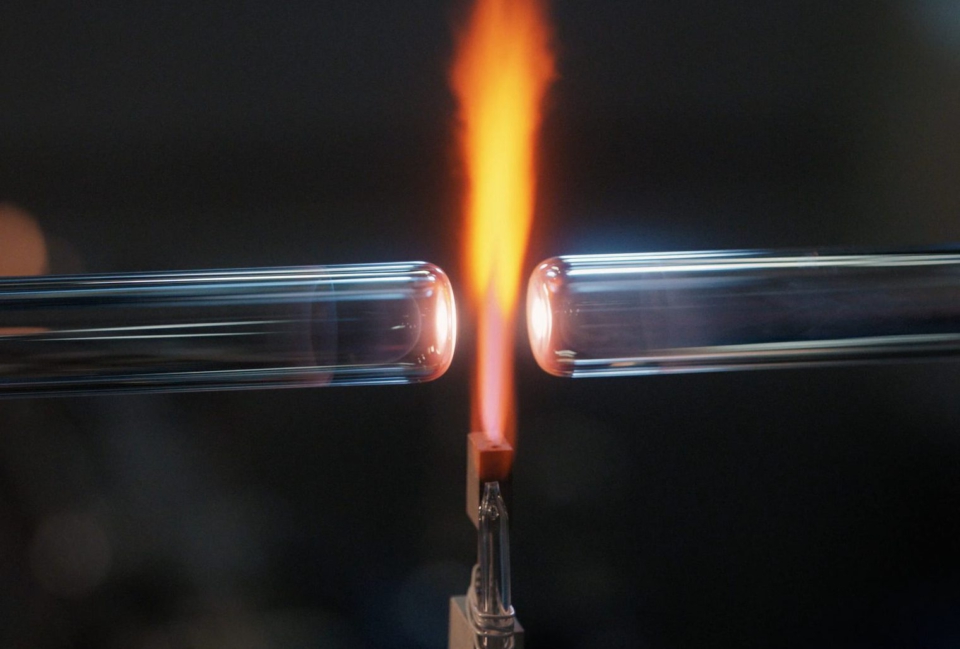

In light of the global Covid-19 pandemic, various air and surface disinfection technologies such as UV-C are now being used (again) in an increasing range of different applications. UV-C light kills viruses and bacteria. Synthetic fused silica or optical quartz enables the best UV transmission.

Ionization technology used for air purification is another example of an existing technology that is currently being used in an increasing range of applications.

Our expertise in machining quartz glass and our in-house laser technologies enable us to help you with the most demanding applications for air purification & surface disinfection.

Typical applications

- Air Purification & Surface Disinfection

Quartz tubes, UV-C windows, ionization tubes - Vacuum Components

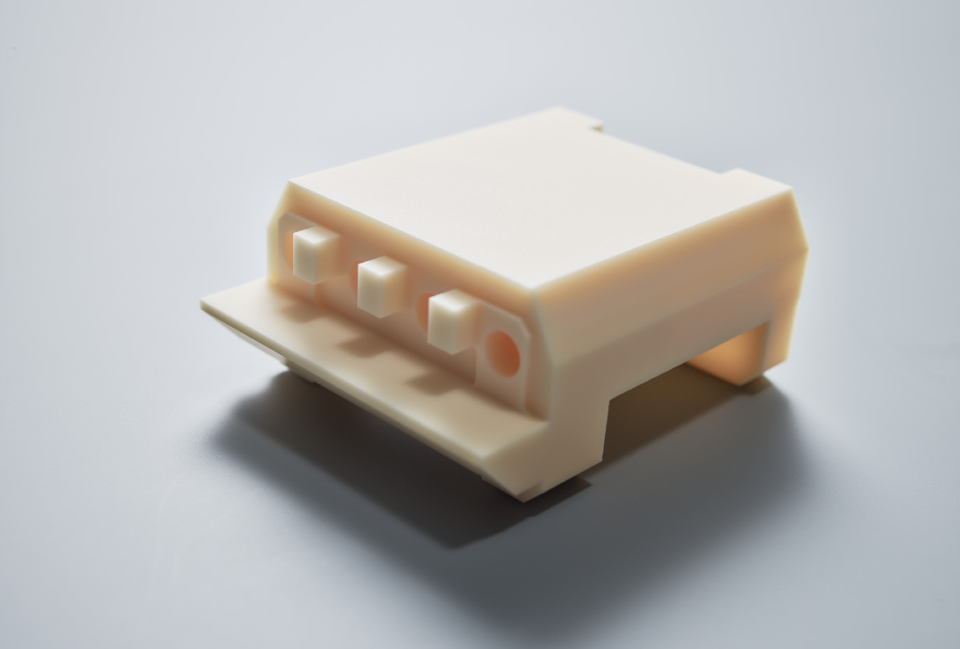

Feedthroughs, vacuum valves - High Pressure Components

Rupture discs, glass barrier plugs, pressure discs - Industrial Glassware

Optical windows, isolators, carriers

Typical materials

- Glass (Borosilicate, Zerodur®, soda lime silica)

- Quartz (Fused silica)

- Macor®

- Aluminium oxide

- Stainless steel (316L & 304)

- Nickel alloy (Hastelloy®)

- Aluminium (5083 & 6082)