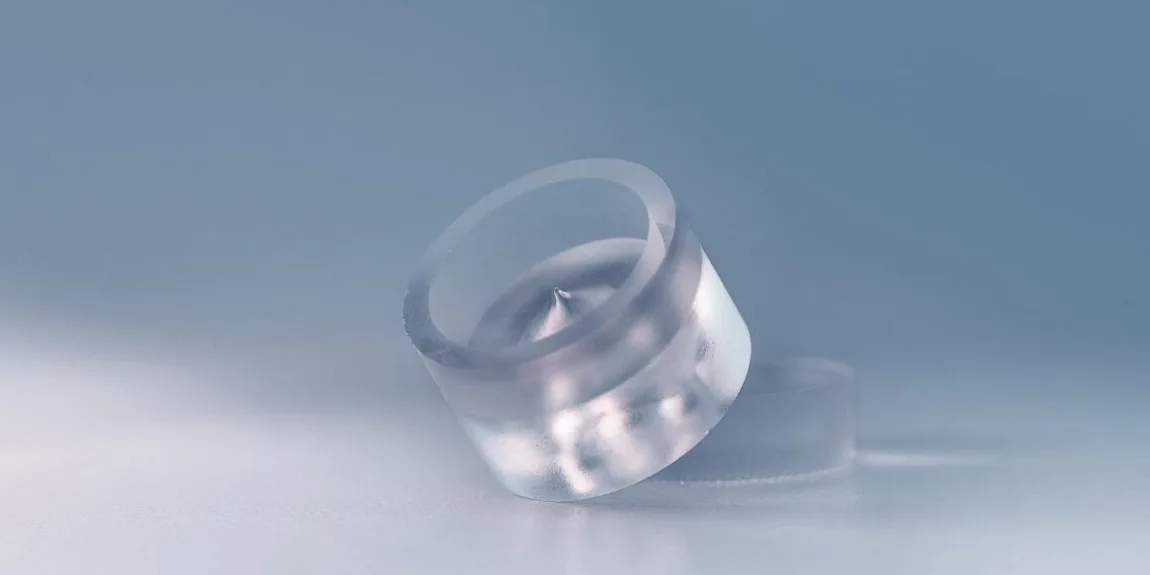

Explore the future with 3D glass printing. We are now able to integrate optical, mechanical, fluidic functionalities at a micron level with 3D Selective Laser-Induced Etching.

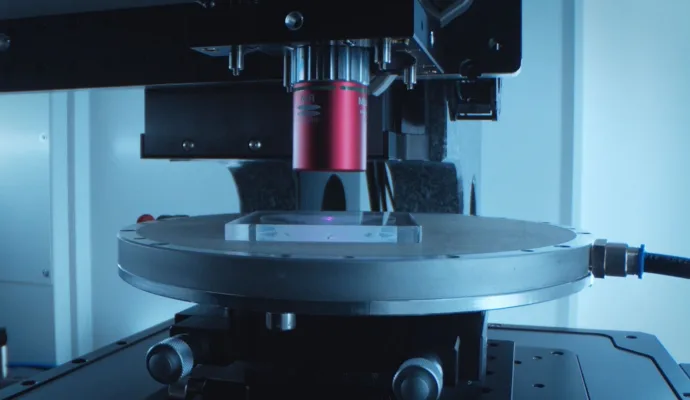

Selective-Laser-Induced Etching (SLE) is a two-step process that allows us to modify the structure inside glass via a pulsed laser beam and selectively remove glass via wet chemical etching. This way, we are able to create microstructures in the third dimension that can among others be used for dispensing technologies, writing of optical patterns, cutting on a micro-scale.

3D free-form manufacturing enables applications such as microvalves, glass-to-glass encapsulation, microchannels and various other MedTech and life science applications. In Photonics, 3D selective laser etching can help solve design challenges for waveguides, couplers and various opto mechatronic alignment systems.

Besides SLE, polishing, bonding, coating and filament cutting are some of the precision glass processing services that can help elevate your Photonics design.

The LouwersHanique engineers have acquired know-how that allows us to manufacture specific 3D structures in glass and ceramics with the smallest possible geometries.

Read more about our laser processing techniques and various micro-assemblies.

Or contact us directly so we can help you!