Precision Quartz Components

Ultra-precise small-scale quartz components for high-tech industries, designed with exceptional thermal and chemical stability for micron-level accuracy.

Advantages of quartz for high-tech manufacturing

Quartz and fused silica are renowned for their exceptional thermal stability, low thermal and electrical conductivity, optical transparency and high chemical purity. These materials also exhibit low coefficient of thermal expansion (0.55 to 0.57 x 10⁻⁶/°C) and can withstand temperatures exceeding 1,200°C without significant structural degradation. This makes quartz and fused silica the material of choice in applications like semiconductor manufacturing and advanced optics, where precision and durability are paramount.

Get our quartz brochure

Superior precision and stability

Both quartz and fused silica maintain their mechanical strength and dimensional stability at high temperatures, withstanding extreme heat fluctuations and thermal shock. With a melting point of 1,710°C for fused silica and 1,670°C for quartz, these materials are essential for industries like advanced photonics and semiconductor processing, where high operating temperatures and thermal cycling are common.

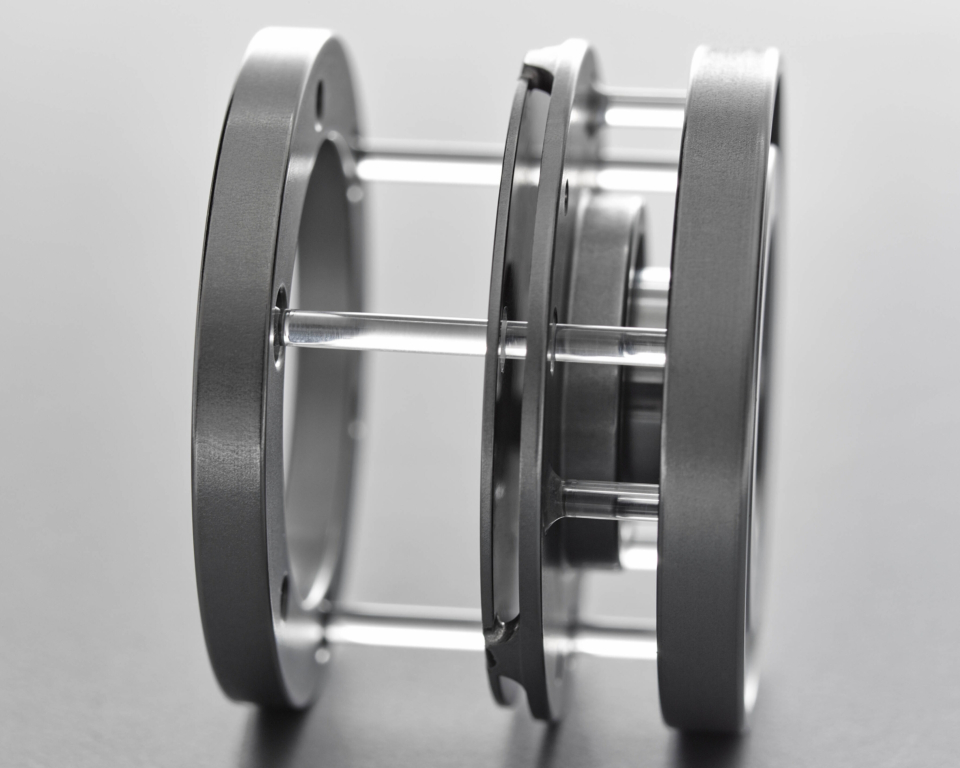

Quartz components, such as torches and reactor tubes, are engineered to resist rapid temperature changes and maintain mechanical integrity, ensuring consistent performance and longevity under extreme conditions.

Why choose quartz and fused silica for critical components?

Quartz and fused silica outperform metals, ceramics, and plastics in key areas that are critical for high-tech applications. Their superior thermal properties, including low thermal expansion and high thermal shock resistance, make them ideal for precision components that must maintain dimensional stability under extreme conditions. Their excellent dielectric strength (470 kV/cm for fused silica) also makes them indispensable in semiconductor and optoelectronics industries, where electrical insulation is critical.

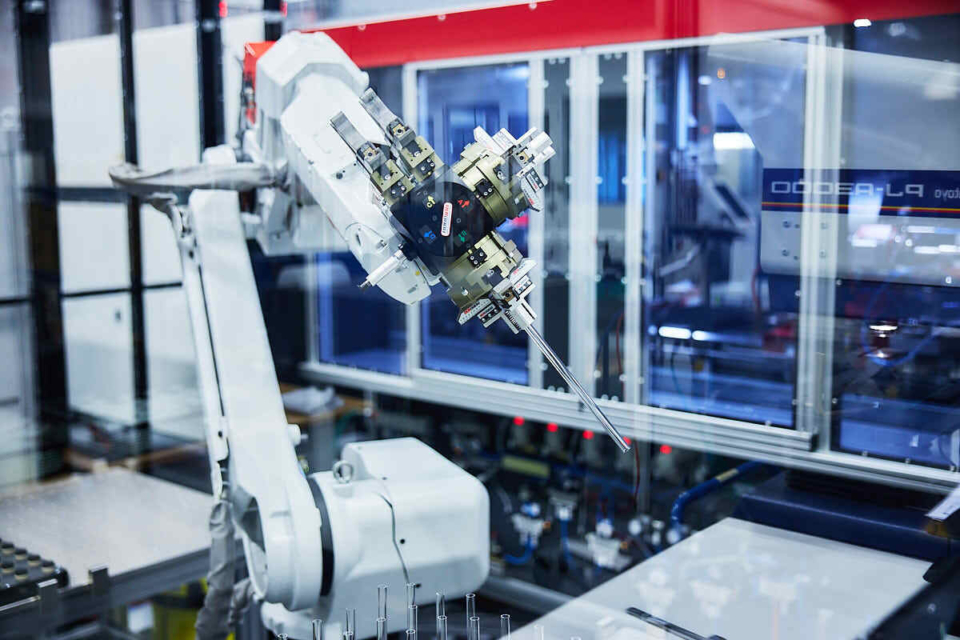

At LouwersHanique we leverage state-of-the-art fabrication techniques to achieve tolerances down to ±5 μm in custom components, ensuring they meet the exacting standards of high-performance applications.

Co-developing quartz technologies

We work closely with your engineering teams to develop custom quartz and fused silica components tailored to your project’s specifications. From initial concept to final production, we ensure precision at every step. Our advanced CNC ductile machining , thermal processing and laser technology, allows us to produce components with extreme accuracy and smooth surface finishes. This is particularly valuable for applications where surface roughness can affect performance, such as optical lenses or reactor tubes.

Additionally, we offer an exclusive Grade 2 cleaning process that ensures components meet the highest purity levels, free of any contamination that could affect their performance in sensitive environments like semiconductor fabrication or energy research.

Typical solutions

We produce a range of high-precision quartz and fused silica components designed for high-performance environments, including:

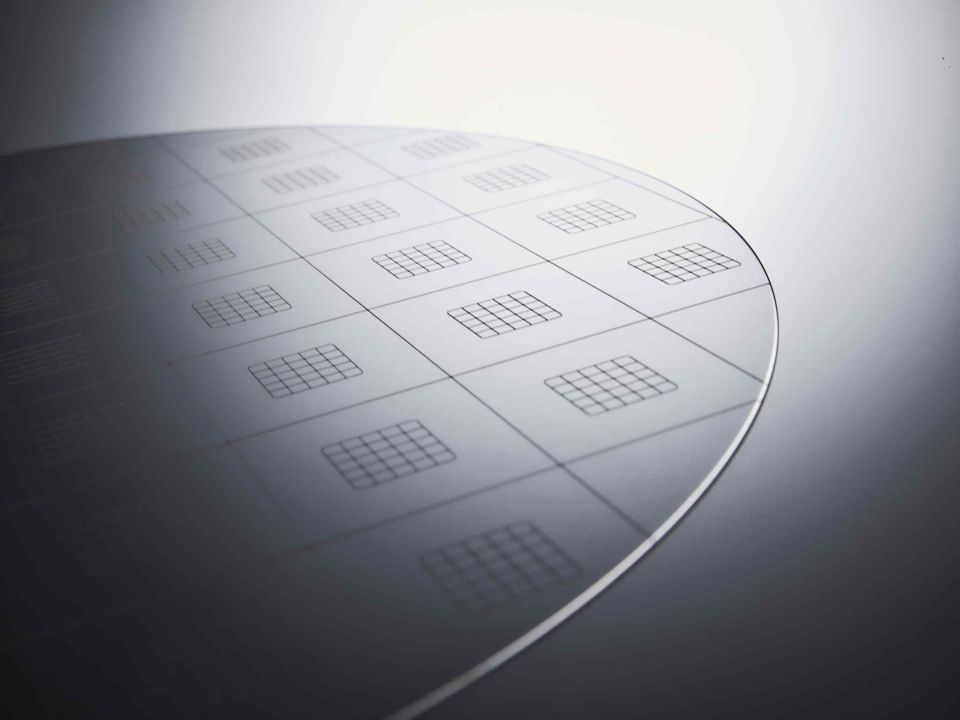

- Micro-lens arrays

- Ampoules for radiation and nuclear applications

- Wafer carriers

- Wafer boat

- Gas diffusers

- Seals and gaskets

- Sensors

- ICP torches and quartz torches

- Reactors and micro reactors

- Quartz injector

Typical applications

- Semiconductor manufacturing

- Advanced optics and photonics

- Medical devices and pharmaceutical process equipment

- Energy research and nuclear technologies

- Chemical processing

- Analytical Instrumentation

Typical material combination

We combine quartz with other advanced materials to optimize performance in high-tech environments. Typical combinations include:

- Quartz and silicon: Enhanced for semiconductor fabrication and wafer handling

- Quartz and alumina: Improved durability in high-temperature and corrosive environments

- Quartz and titanium alloys: High strength and heat resistance for aerospace and defense applications

- Quartz and stainless steel: For enhanced mechanical strength and durability in harsh conditions