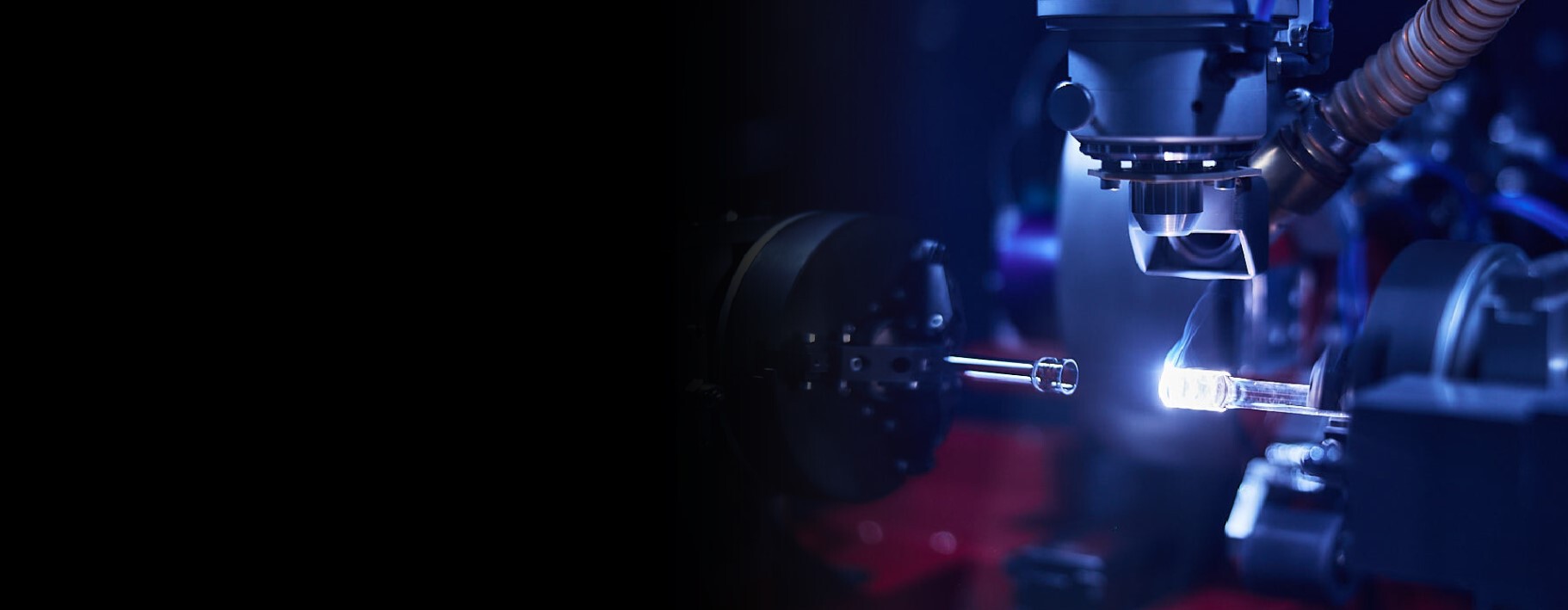

Laser Processing

Combining the latest laser machining technologies enables LouwersHanique to manufacture highly complex glass assemblies and microstructures.

Benefits of laser processing

Get in touch todayLaser processing of quartz and glass allows for novel processing possibilities and complex 3D designs. When it comes to laser processing in the glass processing industry, this usually entails laser drilling and laser cutting via making filaments and material modifications. As the technology evolves, we can now use laser processing to remove the material layer-by-layer using a pulsed laser beam. These new methods are revolutionary to the glass industry as laser processing is a more controlled process than cutting glass or quartz. This opens the world of possibilities for working on miniature scales.

Selective Laser-Induced 3-dimensional etching (SLE)

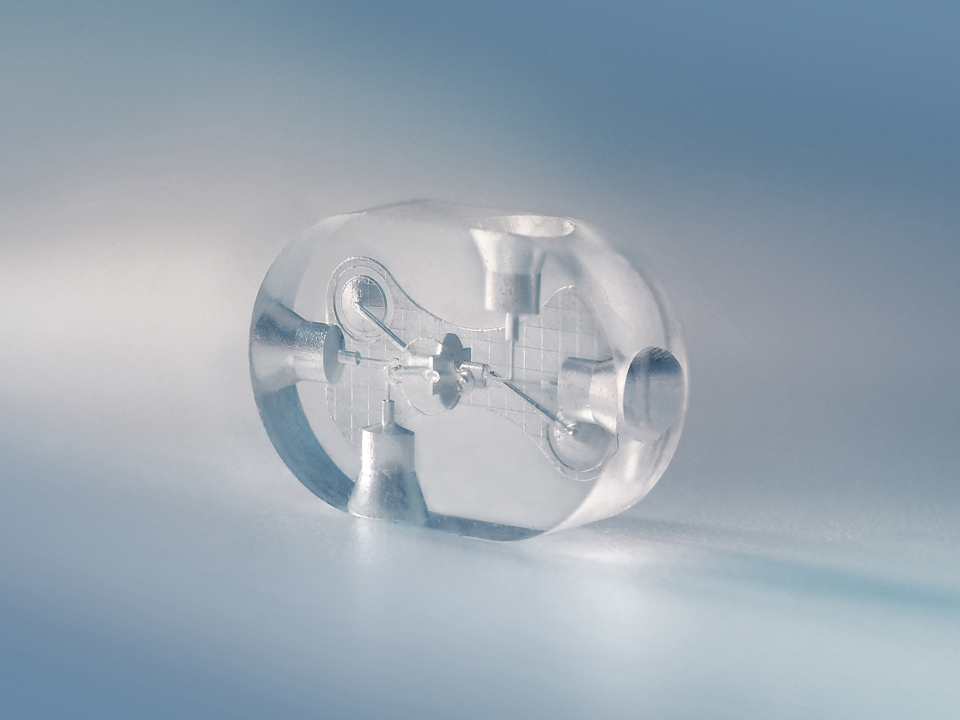

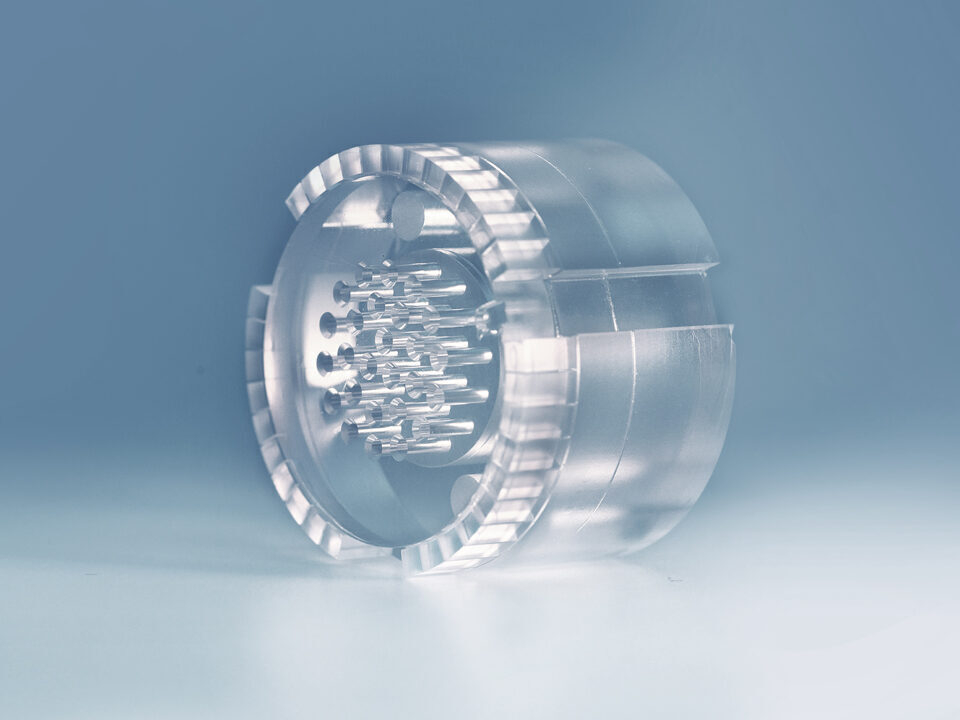

Fused silica and borosilicate offer fantastic optical, thermal, and chemically stable properties which help increase performance at the micro-scale. Selective laser-induced 3-dimensional etching opens up a multitude of possibilities and unique product features. This enables customers to integrate a host of optical, mechanical, and fluidic functionalities. And combined with various joining, processing, and integration processes it simplifies the creation of highly complex 3D microstructures and components.

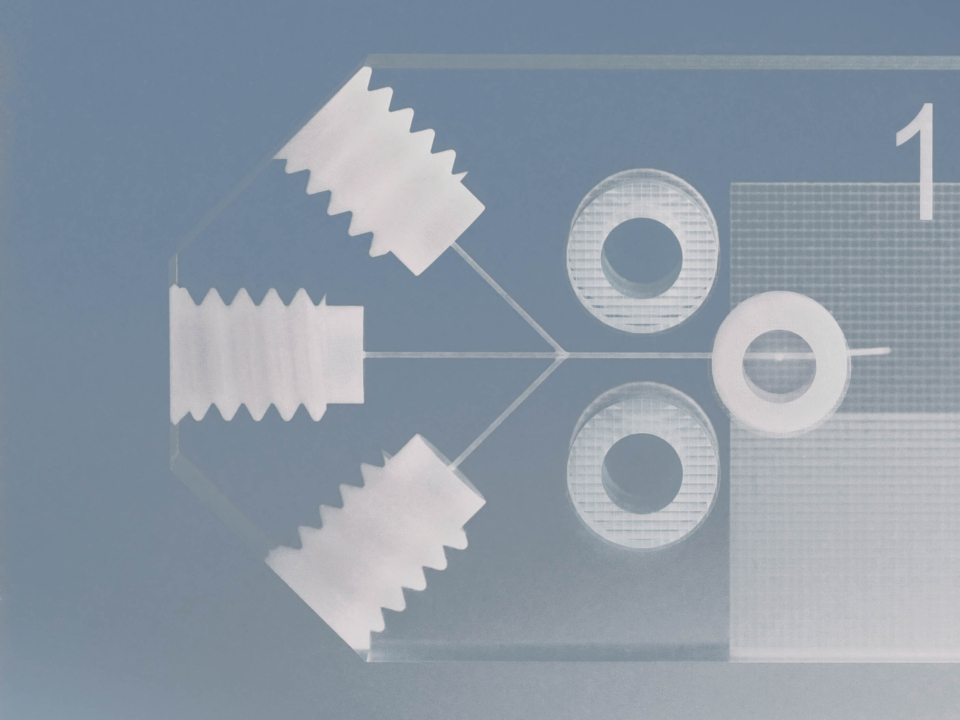

Complex 3D microstructures using Selective Laser-induced Etching

The Selective Laser-induced Etching (SLE) concept was originally developed by the Fraunhofer Institute for Laser Technology (ILT) and can be applied to borosilicate glass, synthetic quartz, sapphire among others. It combines the power and accuracy of femtosecond pulsed laser technology with precision etching technology and special surface finish technologies. Unlike additive 3D printing, Selective Laser-Induced Etching, creates structures inside glass via a femtosecond pulsed laser, to consequently remove these via chemical processing. Unique structures with extreme aspect ratios can be build this way.

Opening the way to micro-functionality

Ever since the first Lab-on-a-Chip developments, 3D microstructures have become increasingly common and complicated. From relatively simple nozzles and valves to complete micro-machined filters, mixing structures and gas dividers, the range of micro-mechanical structures grows almost daily. Regardless of where you are in your product development, LouwersHanique is happy to guide you through the possibilities and build the 3D structure at the heart of your design.

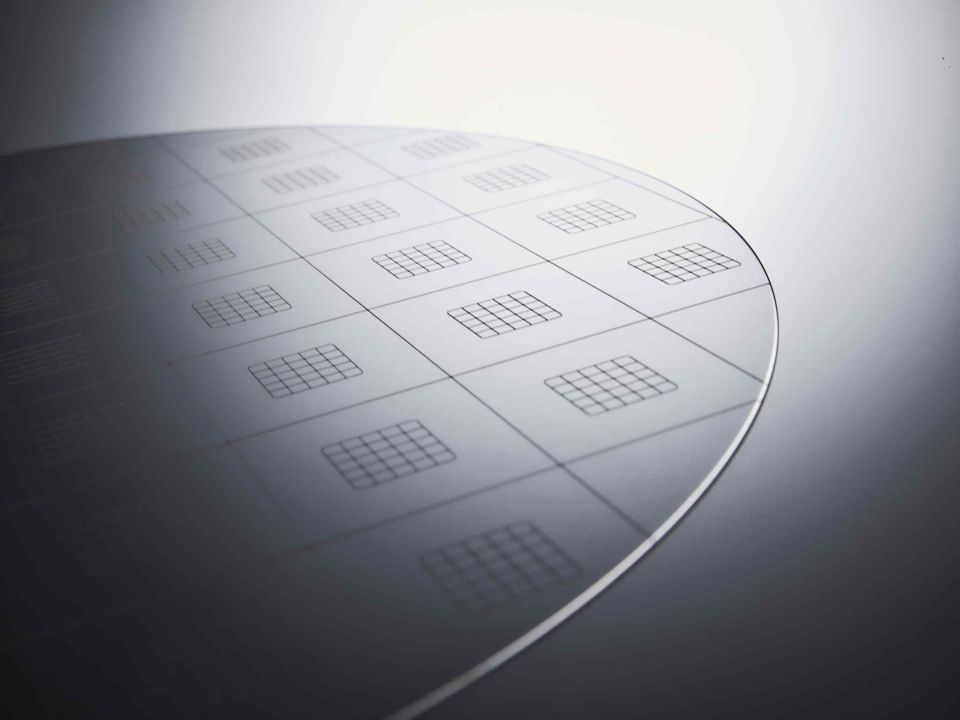

Laser Filament Cutting

Microfabrication of transparent materials is becoming essential. The increasing industrial requirements of micrometer scale services, growing industrial demand and the need of high-quality fast fabrication processes encouraged us to invest in new cutting technologies. In contrast with Laser Cutting, Laser Filament Cutting uses high intensity ultra-short pulse laser technology to effectively change the structure of the glass. This method allows to cut highly-precise and complex contours or patterns from glasses and crystals reducing the production time, chipping and sub-surface damage.

Featured services

- Writing of optical patterns

- Glass-to-glass encapsulation

- Drilling and cutting on a microscale

- Polishing for surface treatment

- 3D free-form manufacturing

- Selective laser-induced etching (SLE)

- CO2 laser services

- CNC laser machining

- Laser filament cutting

Featured Applications

- MEMS (micro-electromechanical systems) and lab-on-a-chip components

- Microfluidic devices

- Optical components

- Injection nozzles

- Cell sorter

- Gas sensor

Featured materials

- Borosilicate glass

- Soda-lime

- Sapphire [Al2O3]

- Quartz (fused silica)

- Zerodur®