Thermal Processing

Our latest glass processing technologies and automated machinery enable us to manufacture glass products of the highest quality and accuracy.

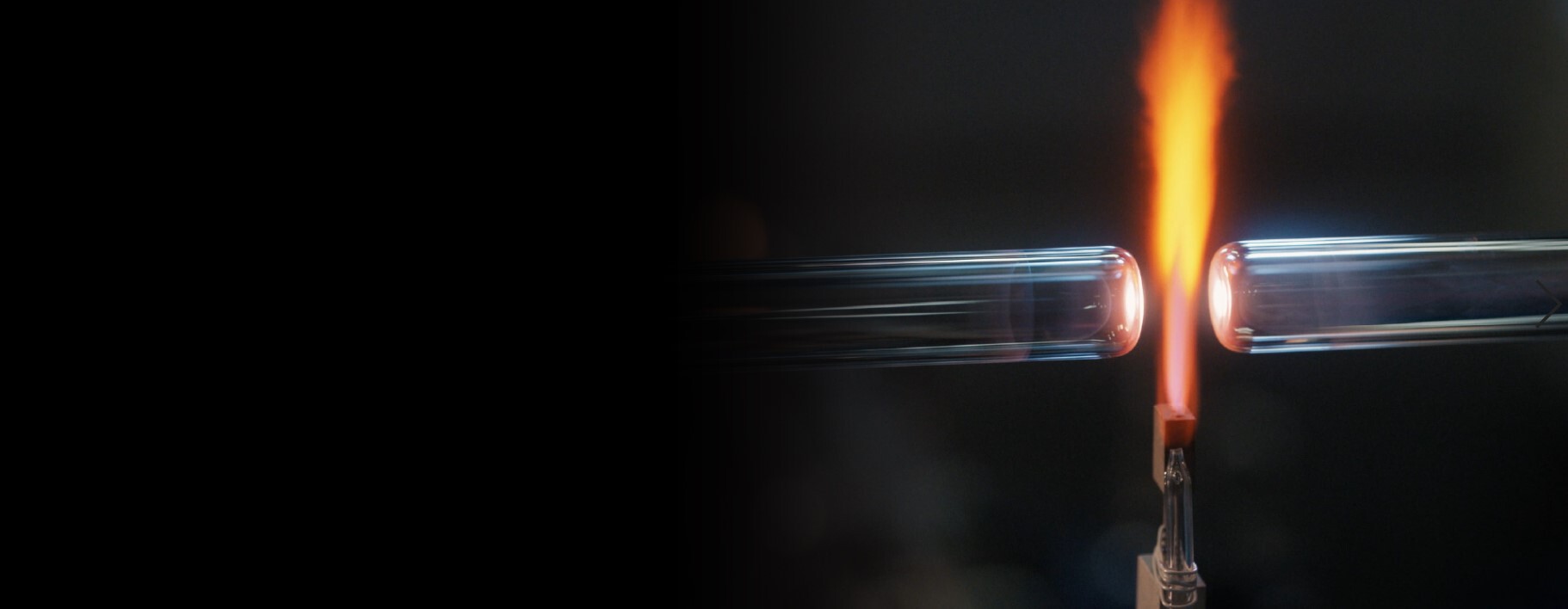

Thermal processing with extreme precision

Traditional thermal processing is centred around craftsmanship and the ability to control heat. LouwersHanique has been in this industry for more than 7 decades and has undergone a transition from traditional craftmanship to automated process-driven production.

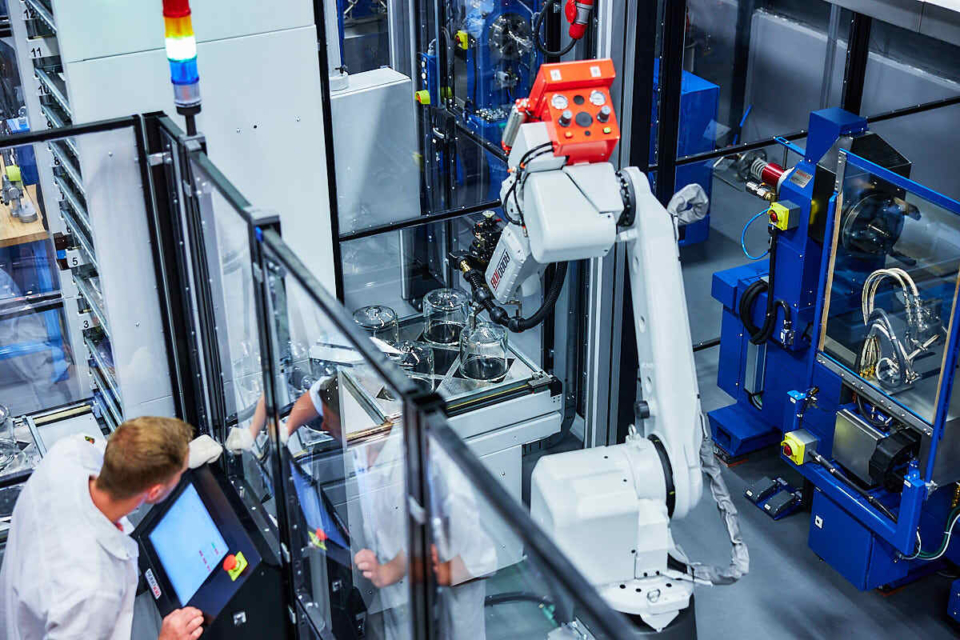

Process-driven production of glass components

Process-driven production and the continuous application of Copy Exact principles and SPC production enable LouwersHanique to consistently achieve the lowest tolerances and quality levels. We combine the latest glass processing technologies with automated thermal processing and skilled craftsmanship. This allows for taking on technical glass processing challenges that were previously considered inconceivable. Starting from large single wall vessels up to a diameter of 240 mm, glass columns, special screw threads, glass housings to micro-components that require 3D free form manufacturing.

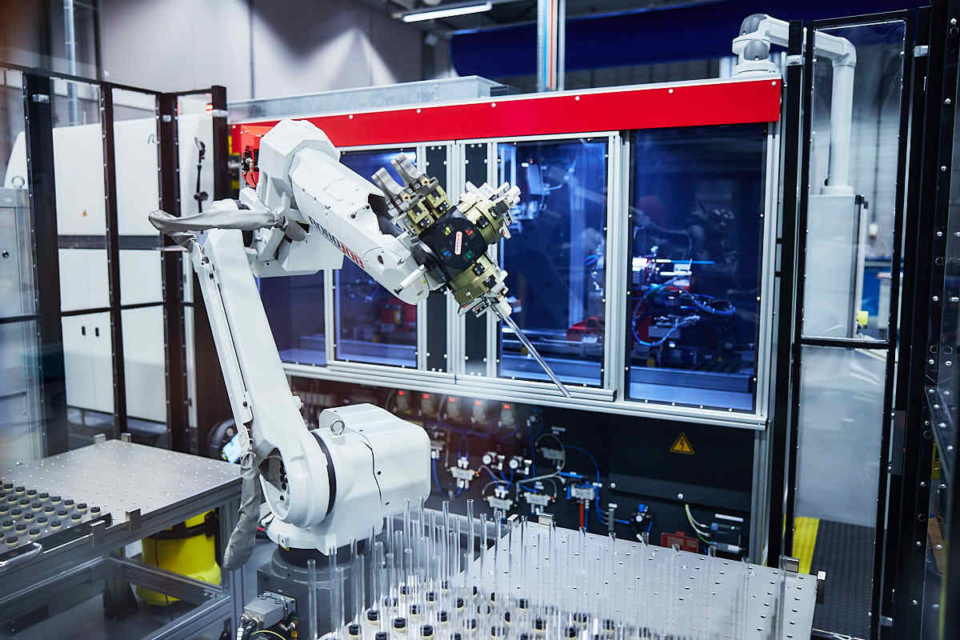

Designed for your application

Glass is carefully chosen based on the desired properties for a given application. In this way, you will always get the optimal material with respect to temperature properties, purity, optical transmission, expansion coefficient, mechanical strength, and chemical resistance. Our R&D engineers will create a product design that fits the required specifications alongside choosing the best production method. At LouwersHanique, many various production methods are available starting from thermal shaping and laser processing technologies to joining of glass and various material combinations including glass-metal, glass-ceramics and many more. Technologies such as Selective Laser-induced Etching and 3D free form manufacturing open a world of possibilities with regards to creating glass and quartz micro-components. However, the development of your glass components does not stop after the initial design. Various tests are conducted inside the cleanrooms to ensure the outstanding performance of a final component.

The starting point is quality materials

LouwersHanique has long-standing strategic collaborations with all the leading glass and ceramics material producers. Ensuring availability of all glass materials including borosilicate and quartz glass, in a variety of differing qualities and gradations.

Borosilicate glass is commonly applied in analytical and synthetic applications in the analytical and biochemical industries because of its unique chemical resistance, auto split ability, optical transparency, biochemical compatibility, and thermal shock resistance.

Alternatively, quartz glass is used where there is demand for very high purities, UV transmission, chemical resistance or temperature resistance. For example in semiconductors, optoelectronics and air and water disinfection.

Featured services

- Thermal resizing

- Thermal polishing technologies

- Filament cutting

- Thermal forming

- Thermal joining

- Laser cutting

- 3D free form manufacturing

Featured components

- Large single wall vessels up to a diameter of 240 mm

- Glass columns

- Special screw threads

- Joints

- Glass housings